Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Deal closed: YZYX70WZ sunflower oil press order for Cuban client

- A Nigerian customer successfully ordered 1tph palm fruit oil milling machines

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

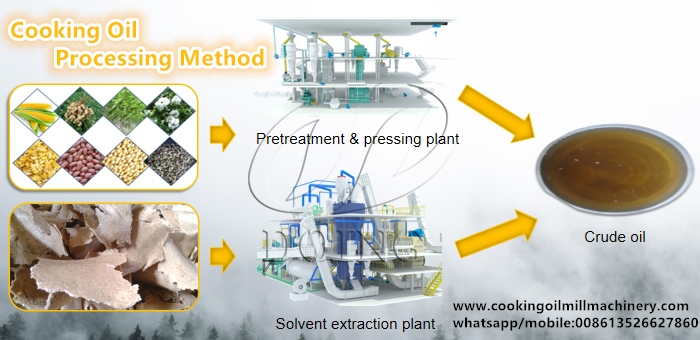

The difference between pressing method and solvent extraction method

The most common methods of cooking oil processing are pressing method and solvent extraction method. There are some differences between pressing method and solvent extraction method.

Two methods of processing cooking oil

Two methods of processing cooking oil

Below are some factors for your reference:

1. Different processing technology:

Pressing is using mechanical pressing to get crude oil out, while solvent extraction is using N-hexane to extract the crude oil out, which belongs to chemical method. No matter using pressing method or solvent extraction method, the final oil you get is crude oil, which need to be refined into edible oil.

2. Different oil residue rate:

After pressing, usually the oil residue in the cake is around 6-7%. By using the solvent extraction method, the oil residue rate can be lower than 1%.

3. Different application range:

Both pressing and solvent extraction can be used to process common oil seeds like soybean, peanut, rapeseed, sunflower, sesame etc.

Relatively, solvent extraction is more suitable for low oil content rate oil seeds like soybean and rice bran for input capacity above 30T/D. As for high oil content rate oil seeds like peanut, sunflower and sesame for input capacity 1-100T/D, it is better to press first, then choose whether adding solvent extraction or not.

4. Different machine cost:

For same input capacity, usually solvent extraction method costs more than pressing method. Because solvent extraction plant is anti-explosion type workshop, which means all the pumps and electric motor inside the plant is anti-explosion type. You can choose the different processing methods according to your budget.

In general, clients can choose different oil processing method according to their different oil seeds and input capacity. Henan Doing Group has professional engineers who can give you some useful advice on choosing the suitable method. If you want to set up the oil factory, please contact us for more details and information.

Leave a message

If you wanna to get more details about The difference between pressing method and solvent extraction method, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line