Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

What are the deacidification methods for oil refining?

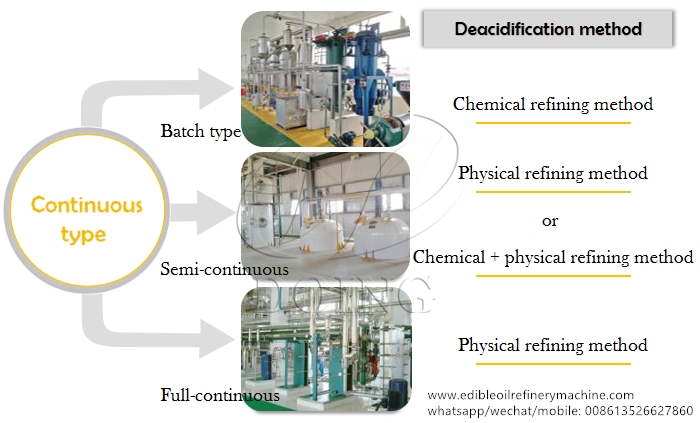

The deacidification methods of oil refining mainly include physical deacidification and chemical deacidification. General physical deacidification is used by steam distillation, and chemical deacidification is used by alkali refining.

(1)Physical deacidification method

·Steam distillation deacidification: This method uses high-temperature steam to remove free fatty acids in the oil under high temperature and vacuum conditions. This method is suitable for refining low-colloid oils, such as coconut oil and rice bran oil, because these oils have a high acid value. If chemical alkali refining is used for deacidification, it will cause excessive loss of neutral oil.

Different types of refining method in edible oil refining process

Different types of refining method in edible oil refining process

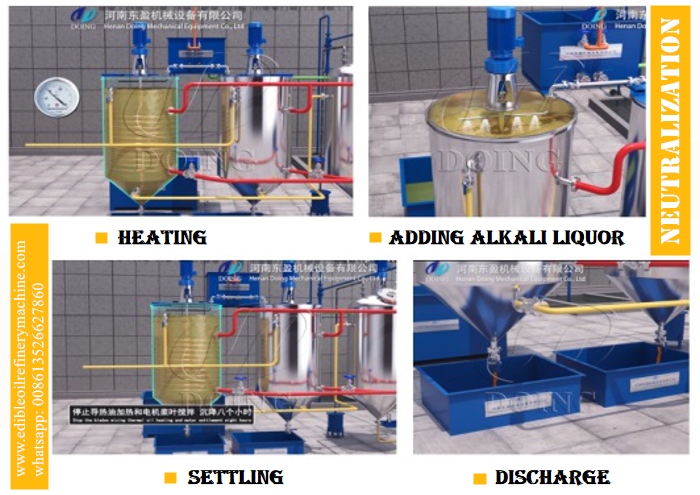

(2)Chemical deacidification method

·Alkali refining deacidification: This is the most commonly used chemical deacidification method. The caustic soda solution is used to neutralize the free fatty acids in the crude oil to generate sodium soap that precipitates in the oil and then separates from the oil. This method can remove most of the free fatty acids, and the generated sodium soap has a good adsorption effect, which can adsorb and remove other impurities in the oil, such as pigments, phospholipids, etc.

Chemical deacidification process of cottonseed oil

Chemical deacidification process of cottonseed oil

(3)Advantages and disadvantages of different methods

·Physical deacidification: The advantages are simple operation and no wastewater discharge, which is suitable for refining low-colloid oils. The disadvantage is that the deacidification effect may not be as thorough as the chemical method.

·Chemical deacidification: The advantage is that the deacidification effect is good and most of the free fatty acids and other impurities can be removed. The disadvantage is that it may cause the loss of some neutral oils and may lead to the loss of some nutrients.

(4)Application scenarios and scope of application:

·Physical deacidification: Suitable for low-colloid oil refining, such as coconut oil, rice bran oil, etc.

·Chemical deacidification: Suitable for most oil refining, especially for scenarios where free fatty acids need to be removed efficiently.

By combining different deacidification methods, oil mills can choose the most suitable process according to specific needs to achieve the best refining effect and economic benefits.

PREV:How to choose the right edible oil extraction machine manufacturer?

PREV:How to choose the right edible oil extraction machine manufacturer?

NEXT:What are the factors affecting the edible oil extraction effect?

NEXT:What are the factors affecting the edible oil extraction effect?

Leave a message

If you wanna to get more details about What are the deacidification methods for oil refining?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.