News

- Deal closed: YZYX70WZ sunflower oil press order for Cuban client

- A Nigerian customer successfully ordered 1tph palm fruit oil milling machines

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

Project Case

- 2TPH palm oil processing plant in Nigeria

- 50TPD soybean oil puffing press production line in Nigeria

- 1TPD cottonseed oil refining machine ordered by our Ugandan customer has been installed

- 5TPD rapeseed oil processing production line successfully installed in Yunnan Province, China

- 5tph palm kernel cracker and separator project and 1tph palm kernel oil making machine project in Uganda

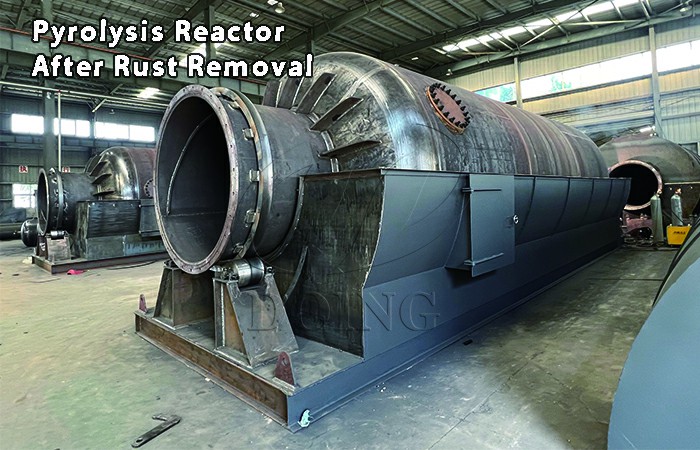

The new rust removal technology empowers Doing’s equipment to a higher level!

Good news! After the meticulous research and many tests of the professional technical team of DOING GROUP, the new rust removal technology has finally been successfully empowered, making the equipment manufactured by DOING achieve new upgrades of equipment anti-corrosion performance and stable performance. The price/performance ratio of the equipment is up to the next level!

Comparison of steel before and after rust removal

Comparison of steel before and after rust removal

In the equipment manufacturing process, the surface treatment of the steel raw materials is one of the key factors that determine the service life of the equipment. In order to make the surface of steel raw materials have good cleanliness and roughness, it is necessary to carry out pretreatment especially rust removal on the surface of the steel.

DOING's latest new rust removal process can not only remove the rust, oxide scale and welding slag on the surface of the steel raw materials, but also eliminate the welding stress of steel. This improves the fatigue strength of the steel raw materials, increases the paint film adhesion when the equipment is painted, and achieves the purpose of improving the corrosion resistance and the internal quality of the equipment.

Finished picture of steel after rust removal

Finished picture of steel after rust removal

DOING GROUP has always been adhering to the concept of "Quality&Customer first", constantly carrying out technological innovation and providing customers with high-quality equipment to help customers get more profits.

Our company's equipment is mainly divided into four major sections: energy recycling equipment, metal plastic separation and recycling equipment, starch and flour processing equipment, or edible oil processing equipment. No matter which sector you want to invest in, DOING can customize the equipment of suitable scale for you. Welcome to contact us for free quotation or visit the factory and test equipment with materials!

PREV:Ugandan customer ordered a set of 350kg/h electric cooker from Henan Glory Company

PREV:Ugandan customer ordered a set of 350kg/h electric cooker from Henan Glory Company

NEXT:Nayong County Government purchased 4.5t/d rapeseed oil processing machine from Henan Glory Company!

NEXT:Nayong County Government purchased 4.5t/d rapeseed oil processing machine from Henan Glory Company!

Leave a message

If you wanna to get more details about The new rust removal technology empowers Doing’s equipment to a higher level!, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line