Blog

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

- Must-know maintenance tips for your soybean oil extraction machine

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- 2tph Drum-type Palm Fruit Threshing Machine: New Order Secured by Henan Doing Nig. Co.,Ltd from Nigeria

- Shipping Confirmation: Mini Palm Oil Processing Line Successfully Handed Over from Our Nigeria Branch

- Heading to Kenya! Henan Glory's Custom Sunflower Oil Extraction Equipment Is On the Move

- Shipment Update: Small Scale Palm Oil Mill Plants Successfully Shipped to Nigeria

- Tailored for 1TPD: Henan Glory Wins Nigerian Small Scale Palm Oil Production Equipment Order

Batch type edible oil refining machine 1tpd to 20tpd

Ready to transform your crude oil into a clear, stable, and market-ready product? Henan Glory's 1-20tpd batch type edible oil refining machine is tailored for small edible oil producers, offering a cost-effective, flexible solution for refining high-quality edible oil.

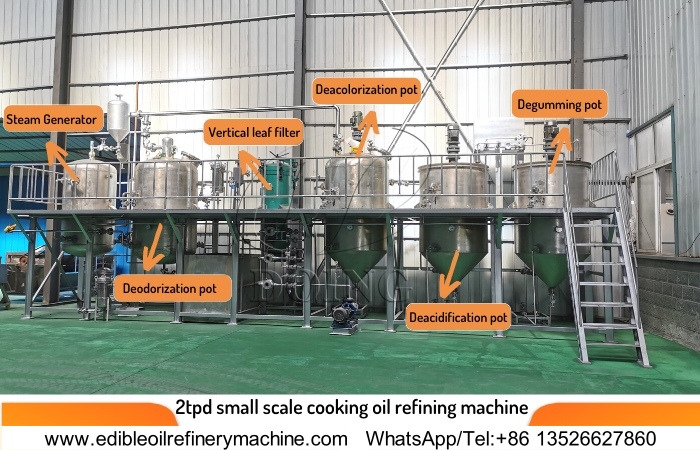

Adopting the same core refining process as large-scale refining equipment, this batch type edible oil refining machine includes four key sections—degumming, deacidification, bleaching, and deodorization—to thoroughly purify crude oil. Each section targets specific impurities, laying a solid foundation for high-quality oil.

Degumming removes gelatinous impurities like phospholipids via hydration, effectively preventing the oil from foaming, smoking, or discoloring during heating. Deacidification uses alkali liquor for neutralization to eliminate free fatty acids (FFA), enhancing the oil's stability and preventing rancidity. Bleaching relies on the adsorption of activated clay to remove pigments such as chlorophyll and carotenoids, improving the oil's appearance. Deodorization employs vacuum distillation to strip undesirable odor-causing substances (e.g., oil oxidation products). The deodorization tank is made of 304 stainless steel, which itself resists corrosion and oxidation. When combined with the vacuum environment, the tank effectively prevents the oil from re-oxidizing at high temperatures.

Batch type edible oil refining machine

Batch type edible oil refining machine

After undergoing these four systematic processes, the final refined oil fully meets national standards, while preserving the inherent nutrients of the raw oil well and ensuring its cleanliness and safety.

It's worth mentioning that Henan Glory's batch type edible oil refining machine offers two tailored heating methods to meet the needs of different production scales. For small-scale operations with a daily output of no more than 2tpd, electric heating models (available in 0.5, 1, and 2tpd specifications) are the optimal choice—they feature low investment and an all-stainless-steel construction, perfectly meeting the budget and production needs of small workshops. For larger-scale production of 1 to 20 TPD, heat transfer oil heating models are more suitable, as they use a thermal oil furnace and heating coil system, ensuring efficient, stable heating of large batches of oil with low energy consumption.

2tpd batch type edible oil refining machine

2tpd batch type edible oil refining machine

Additionally, the batch type edible oil refining machine integrates an eco-friendly closed system design. This minimizes exhaust emissions and oil residue pollution, aligning with modern stringent environmental standards—helping you reduce environmental management costs.

Finally, its batch-by-batch design enables frequent crude oil switching—whether processing soybean, sunflower, peanut, or palm oil—without complex adjustments. This agility lets you quickly respond to market shifts and expand your product range.

For the batch type edible oil refining machine's detailed specifications, customized configurations, and the latest pricing, please contact us—we're ready to provide tailored solutions for your production needs.

PREV:What is the working principle of crude palm kernel oil expeller?

PREV:What is the working principle of crude palm kernel oil expeller?

NEXT:Must-know maintenance tips for your soybean oil extraction machine

NEXT:Must-know maintenance tips for your soybean oil extraction machine

Leave a message

If you wanna to get more details about Batch type edible oil refining machine 1tpd to 20tpd, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.