Blog

- Ultimate Guide to Palm Kernel Oil Processing Machines: Types & How They Work

- What is the working principle of crude palm kernel oil expeller?

- Batch Type Edible Oil Refining Machine 1TPD to 20TPD

- Must-Know Maintenance Tips for Your Soybean Oil Extraction Machine

- Crude Oil Refining Equipment: Key Machines & Their Roles

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Shipping Confirmation: Mini Palm Oil Processing Line Successfully Handed Over from Our Nigeria Branch

- Heading to Kenya! Henan Glory's Custom Sunflower Oil Extraction Equipment Is On the Move

- Shipment Update: Small Scale Palm Oil Mill Plants Successfully Shipped to Nigeria

- Tailored for 1TPD: Henan Glory Wins Nigerian Small Scale Palm Oil Production Equipment Order

- Benin Vegetable Oil Supplier Enhances Product Purity with Henan Glory's Filtration Equipment

Which sunflower seeds are best for oil extraction?

There are actually about 70 species of sunflowers in the world today, but not all of them produce sunflower oil. Sunflower varieties fall into two main categories: oilseed and non-oilseed. Oilseed sunflower produces solid black seeds with a high oil content, which are best for oil extraction. If you are interested in the sunflower oil production business, the next reading will provide you with more information on sunflower oil extraction.

Different varieties of sunflower seeds

Different varieties of sunflower seeds

The optimal temperature for sunflower seeds before pressing is 120 degrees Celsius, and the moisture content is 2-5%. This requires a different pretreatment before pressing.(Recommend reading: Sunflower oil processing plant)

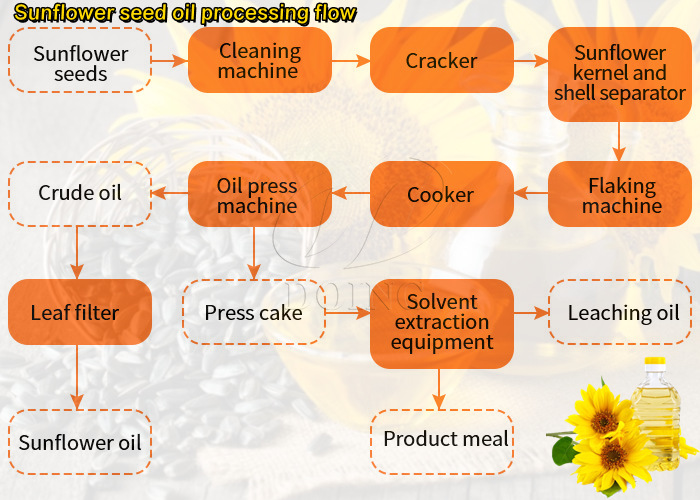

Sunflower oil production process

Sunflower oil production process

►1. Cleaning raw materials: Different equipment is required to remove impurities, metals, etc. from raw materials. On the one hand, it is to reduce the working pressure of subsequent equipment, and on the other hand, it is to ensure the quality of oil products. The second step is cracking, but there are some shells in the raw material that are more suitable for pressing, and the shells also contain oil.

►2. Crushing and rolling: Crushing is to break the raw material into small pieces, and then use a roller to press the raw material into a flat shape, in order to improve the oil yield.

►3. Steaming and frying: Under the condition of high temperature and high steam, the raw material reaches the best state before pressing.

►4. Pressing: The heated coarse powder is continuously fed into the screw press. As the oil is squeezed through slots in the barrel, it is collected.

Sunflower seeds (with shell) can contain up to 45% oil. It is rich in nutrients, and modern technology has fully mastered how to efficiently process these raw materials to obtain high-quality oil. Henan Glory Company have been focusing on this industry for nearly two decades, and have helped our customers set up many factories in Africa and Southeast Asia. If you need sunflower oil production equipment, please contact us.

PREV:What do you need to know in advance before processing sunflower oil?

PREV:What do you need to know in advance before processing sunflower oil?

NEXT:How to start a small cooking oil manufacturing business?

NEXT:How to start a small cooking oil manufacturing business?

Leave a message

If you wanna to get more details about Which sunflower seeds are best for oil extraction?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.