Blog

- Ultimate Guide to Palm Kernel Oil Processing Machines: Types & How They Work

- What is the working principle of crude palm kernel oil expeller?

- Batch Type Edible Oil Refining Machine 1TPD to 20TPD

- Must-Know Maintenance Tips for Your Soybean Oil Extraction Machine

- Crude Oil Refining Equipment: Key Machines & Their Roles

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Shipping Confirmation: Mini Palm Oil Processing Line Successfully Handed Over from Our Nigeria Branch

- Heading to Kenya! Henan Glory's Custom Sunflower Oil Extraction Equipment Is On the Move

- Shipment Update: Small Scale Palm Oil Mill Plants Successfully Shipped to Nigeria

- Tailored for 1TPD: Henan Glory Wins Nigerian Small Scale Palm Oil Production Equipment Order

- Benin Vegetable Oil Supplier Enhances Product Purity with Henan Glory's Filtration Equipment

What machines does the cooking oil press production line include?

Cooking oil press production line contains three main parts: oil seeds pretreatment, oil pressing, and oil filtration. But different oil seeds need to use different equipment in the oil seeds pretreatment stage, so if you want to buy cooking oil press production line, you should tell us what is your oil seeds, and then our engineers will give you suitable suggestion.

If your capacity is more than 20 tons per day, you need choice a whole line to process your oil seed. The complete cooking oil press production line including oil seeds cleaning machine, cracker, flaking machine, cooking machine, oil press machine and filter machine. The oilseed will be very easy to get the oil after pretreatment.

Cooking oil press production line photo

Cooking oil press production line photo

Such a cooking oil press production line can produce high quality pressed oil, but the residual oil rate is about 6-7%. If you want to get more oil out and the economy allows, you can choose pre-press and solvent extraction method.

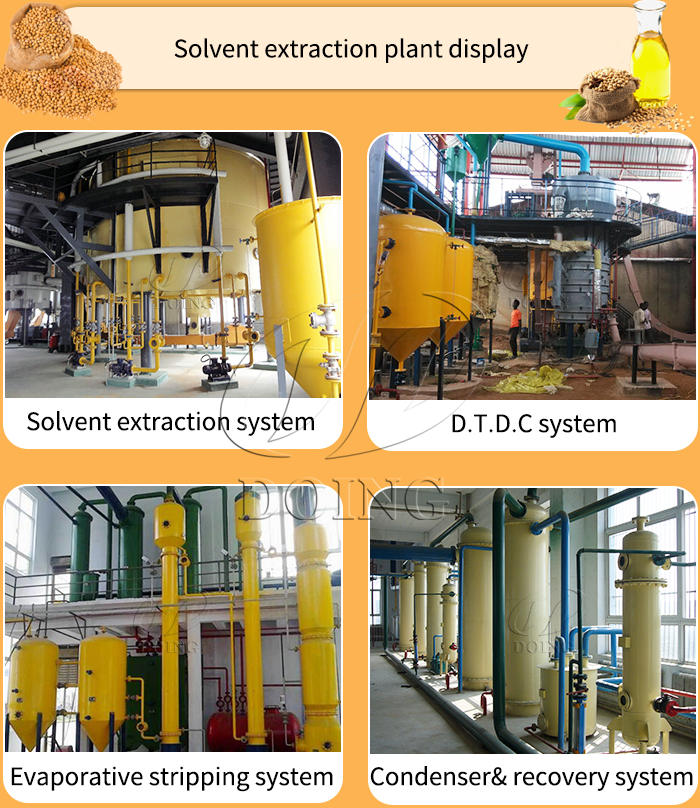

After pre-pressing, the residual oil rate is about 15%, and then through solvent extraction, the residual oil rate can achieve 1%. The oil seed cakes enter the solvent extractor. The extractor fully mixes the n-hexane with the oil by spraying n-hexane, so as to extract the oil from the oil cakes, and the obtained mixed oil will evaporate the n-hexane from the oil by evaporative stripping. The evaporating and stripping equipment includes a first evaporator, a second evaporator, a flash box, etc. Finally, the solvent in the meal is evaporated through the evapo-separated machine or DTDC, and finally the solvent is recovered and recycled.

Cooking oil solvent extraction plant combination diagram

Cooking oil solvent extraction plant combination diagram

If you want the oil to be refined, we also have cooking oil refining machine with different capacity. Small scale cooking oil refinery machines have electrical type and oil conduction type. Refining can enhance oil storage stability, improve oil flavor, improve grease color, and provide raw materials for deep-processed oil products. After refining, your cooking oil can be sold to the market directly.(Recommend reading: Sunflower oil processing plant)

The refining process of cooking oil refinery machine:

1. Degumming: The process of removing peptized impurities from the crude oil is called degumming.

2. Deacidification: There is always a certain amount of free fatty acids in vegetable oils, deacidification is to reduce the oily fatty acids in the oil.

3. Decolorization: Oil decolorization commonly used adsorption decolorization method. The principle of the adsorption decolorization method is to use an adsorbent with strong adsorption such as activated clay to remove the adsorbed pigments and impurities while filtering and removing the adsorbent.

4. Deodorization: removal of small molecule odors in oil.

Above is the whole overview of cooking oil press production line. Our equipment can be adjusted to different degrees according to customer requirements, until customer satisfaction is achieved. If you are interested in cooking oil production, you can contact us at any time, and we will provide you with the best service and quality.

PREV:How is a peanut oil processing plant like?

PREV:How is a peanut oil processing plant like?

NEXT:What do you need to know in advance before processing sunflower oil?

NEXT:What do you need to know in advance before processing sunflower oil?

Leave a message

If you wanna to get more details about What machines does the cooking oil press production line include?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.