FAQ

- Upgrade your edible oil plant: top refining equipment to maximize product value

- Which sunflower oil making machines should I use to invest in sunflower oil production?

- Key steps in peanut oil production: from raw material to refined oil

- How to choose the suitable cooking oil press machine?

- What are the factors affecting the peanut oil extraction effect?

Project Case

- 50TPD soybean oil puffing press production line in Nigeria

- 1TPD cottonseed oil refining machine ordered by our Ugandan customer has been installed

- 5TPD rapeseed oil processing production line successfully installed in Yunnan Province, China

- 5tph palm kernel cracker and separator project and 1tph palm kernel oil making machine project in Uganda

- Complete small scale edible oil production line project in China

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Nigerian customer purchased a 30tpd soybean oil pressing line from Henan Glory Company

- Good News: YZYX70 cooking oil press machine sold to customer in Malawi!

- Successful Partnership: Ghanaian Client Chose Henan Glory's Cooking Oil Press Machine

- Nigeria customer successfully ordered 500kg/h diesel engine powered palm oil press machine from Henan Glory company

- Henan Glory Company shipped 20tpd peanut oil production machines to Sudan

Peanut oil processing plant

Peanut oil processing plant

Peanut / groundnut

Peanut / groundnut

Peanut also called groundnut, is one kind of oilseed with high oil content and high nutritive value. The peanut kernel has 40%-51% oil content, which is also one of the most widely used oilseeds.

Because of the high oil content, two types of the processing technology can both used in peanut oil production: pressing method and solvent extraction method. Which method used depends on your requirement and the capacity you want.

Henan Doing Company supplies the peanut oil processing plant with the input capacity from 10tons/day to 2000tons/day.

The input capacity and the equipment we recommend are as follows:

| Input capacity | Equipment we recommend |

| 100-500kg/hour | Screw oil press machine or integrated oil press machine |

| 10-30tons/day | Peanut pretreatment and oil pressing plant |

| 50-2000tons/day | Peanut pretreatment, oil pre-pressing and solvent extraction plant |

The whole peanut oil processing factory includes pretreatment plant, solvent extraction plant and refinery plant.

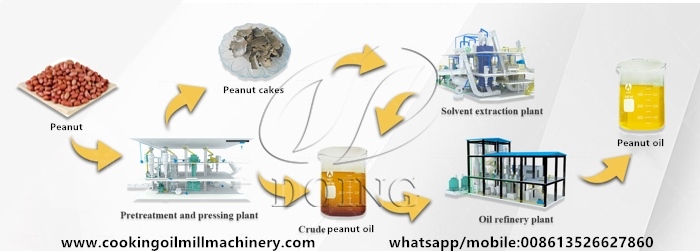

Peanut oil manufacturing process flow chart

Peanut oil manufacturing process flow chart

1) Peanut pretreatment and oil pressing workshop:

The processing steps of peanut pretreatment and oil pressing workshop: Shelling- separating shells and kernels- cleaning- crushing- flaking- cooking- oil pressing or pre-pressing.

The machines used in peanut pretreatment and oil pressing workshop

The machines used in peanut pretreatment and oil pressing workshop

2) Peanut oil solvent extraction workshop:

After the pre-treatment, the next step is solvent extraction, which is using the solvent to exact oil from the peanut cakes. By this kind of technology, the residual oil ratio in the oil meal is less than 1%.

Peanut oil solvent extraction plant and working process flow chart

Peanut oil solvent extraction plant and working process flow chart

3) Peanut oil refinery plant:

After solvent extraction, there are some impurities in crude peanut oil. To get the higher quality final product oil, the crude peanut oil should be refined by oil refinery plant.

It includes four steps of Degumming-Deacidification-Decolorization-Deodorization.

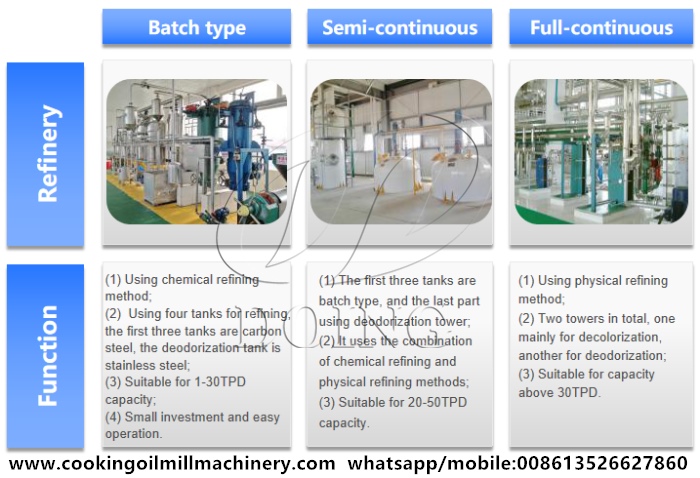

And there are three types of the refinery equipment: batch type, semi-continuous type and full-continuous type.

The three types of peanut oil refinery plant

The three types of peanut oil refinery plant

If you are interested in building a peanut/groundnut oil processing plant, please contact us. We will supply the professional service for you.

Related product recommend

Leave a message

If you wanna to get more details about High quality peanut oil processing machine, peanut oil refinery plant for sale with fractory price, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.