Blog

- Ultimate Guide to Palm Kernel Oil Processing Machines: Types & How They Work

- What is the working principle of crude palm kernel oil expeller?

- Batch Type Edible Oil Refining Machine 1TPD to 20TPD

- Must-Know Maintenance Tips for Your Soybean Oil Extraction Machine

- Crude Oil Refining Equipment: Key Machines & Their Roles

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Shipping Confirmation: Mini Palm Oil Processing Line Successfully Handed Over from Our Nigeria Branch

- Heading to Kenya! Henan Glory's Custom Sunflower Oil Extraction Equipment Is On the Move

- Shipment Update: Small Scale Palm Oil Mill Plants Successfully Shipped to Nigeria

- Tailored for 1TPD: Henan Glory Wins Nigerian Small Scale Palm Oil Production Equipment Order

- Benin Vegetable Oil Supplier Enhances Product Purity with Henan Glory's Filtration Equipment

Key steps in peanut oil production: from raw material to refined oil

Peanut oil, known for its rich flavor and high smoke point, is a favorite in kitchens around the world. Behind every drop of golden, pure peanut oil lies a precise and carefully managed production process. Whether you're looking to start an edible oil business or upgrade your current production line, understanding the key steps in peanut oil production is essential for achieving premium quality and high efficiency.

Step 1. Raw material selection and pretreatment

The first key step in peanut oil production is pretreatment. High-quality peanut oil is inseparable from high-quality peanut raw materials. After multiple cleaning and screening, impurities and skins are removed to ensure the purity and quality of peanuts.

Shelling: Most oil seeds need to be shelled before oil extraction. Shelling can not only increase the production capacity of peanut oil production machine and improve its efficiency, but also reduce the wear of peanut oil pressing machine. Shelling machine are commonly used in peanut oil pretreatment process.

Cleaning: Peanut oil pretreatment process we need cleaning machines, such as magnetic selectors, de-stonner and magnetic selector. These cleaning machines can help remove some impurities such as leaves, stones, sand, dirt, spoiled seeds and metal contaminants. The cleaning part avoids damage to other peanut oil production machines.

Crushing: Crushing is generally used for oil seeds with larger particles. This process requires the crusher to squeeze, bend, impact and shear to break the material into small particles.

Flaking: The purpose of flaking is to increase the contact area between the peanuts and the roaster and destroy the internal structure of the peanut cells, so as to facilitate the peanut oil pressing machine to press the peanuts.

Roasting: The peanut roasting machine can adjust the temperature and moisture of the peanuts. The peanut roasting process can make it reach the best situation. After that, we can send the prepared peanuts to the peanut oil press machine to squeeze out peanut oil.

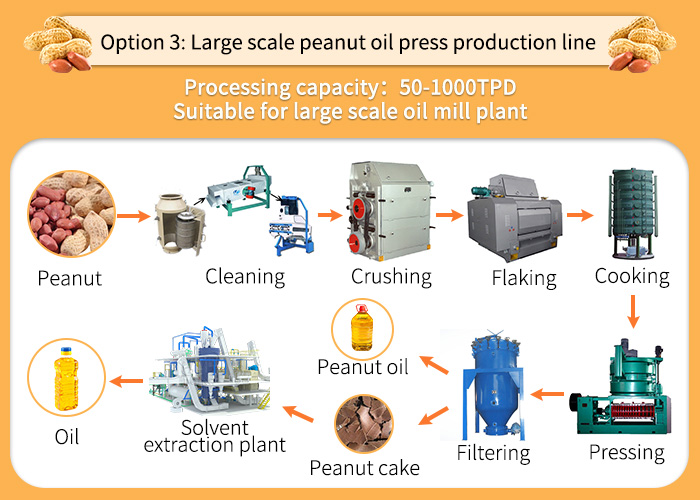

Large scale peanut oil press production line

Large scale peanut oil press production line

Step 2. Pressing and solvent extraction

The second key step in peanut oil production is pressing and solvent extraction, the oil residue in the peanut cake after pressing is about 7%. The peanut cake can be extracted by solvent to get more oil. The pressing process retains more natural nutrients, while the solvent extraction process can increase the oil extraction rate and effectively remove moisture and impurities from peanuts. Our company uses modern pressing and solvent extraction technology to extract the essential oils from peanuts. The press we use adopts high-efficiency and low-temperature pressing technology, which can retain the natural nutrients in peanuts to the greatest extent, reduce heat loss, and ensure the fresh taste of peanut oil. The biggest feature of our Henan Glory Company's peanut oil pressing machine is low energy consumption and less occupied area, so it is the first choice for peanut pressing. Our solvent extraction technology can effectively improve the oil extraction rate and minimize the impurities remaining in the oil to ensure the purity of the oil.

Step 3. Refining

The third key step in peanut oil production is refining. After solvent extraction, there are some impurities in crude peanut oil. To get the higher quality final product oil, the crude peanut oil should be refined by oil refinery plant. It includes four steps of Degumming-Deacidification-Decolorization-Deodorization.And there are three types of the refinery equipment: batch type, semi-continuous type and full-continuous type. Refining is a key step to remove impurities, odors, pigments and other unnecessary components in peanut oil. Our company uses advanced refining equipment to make peanut oil clearer and more transparent, with better taste and in line with health standards through deodorization, decolorization, deacidification and other treatments.

As a common edible oil, peanut oil is favored by consumers for its unique flavor and nutritional value. The modern peanut oil production process combines traditional craftsmanship with modern technology to ensure product quality and safety. The above are the key steps from peanut raw materials to refined peanut oil production. If you have any questions about the process of making refined peanut oil or peanut oil refining machine, welcome to contact Henan Glory Company. You can choose it based on your the quality of crude oil, the requirement of the process of making refined peanut oil and your budget, and our sales and engineer will give you suitable choice.

Leave a message

If you wanna to get more details about Key steps in peanut oil production: from raw material to refined oil, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.