FAQ

- Upgrade your edible oil plant: top refining equipment to maximize product value

- Which sunflower oil making machines should I use to invest in sunflower oil production?

- Key steps in peanut oil production: from raw material to refined oil

- How to choose the suitable cooking oil press machine?

- What are the factors affecting the peanut oil extraction effect?

Project Case

- 50TPD soybean oil puffing press production line in Nigeria

- 1TPD cottonseed oil refining machine ordered by our Ugandan customer has been installed

- 5TPD rapeseed oil processing production line successfully installed in Yunnan Province, China

- 5tph palm kernel cracker and separator project and 1tph palm kernel oil making machine project in Uganda

- Complete small scale edible oil production line project in China

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Nigerian customer purchased a 30tpd soybean oil pressing line from Henan Glory Company

- Good News: YZYX70 cooking oil press machine sold to customer in Malawi!

- Successful Partnership: Ghanaian Client Chose Henan Glory's Cooking Oil Press Machine

- Nigeria customer successfully ordered 500kg/h diesel engine powered palm oil press machine from Henan Glory company

- Henan Glory Company shipped 20tpd peanut oil production machines to Sudan

Soybean oil processing plant

Soybean oil processing plant

Soybean

Soybean

Soybean is one of the most common oil seeds around the world, which contains around 16-24% oil.

The oil content rate of soybean is not very high, so according to the amount of your raw materials that you want to process per day, the engineers of Henan Doing Company give some suggestions as below:

|

Processing Capacity (Tons Per Day) |

Equipment that we suggeste |

|---|---|

| Below 10tpd | Screw oil presser |

| 10-20tpd | Screw oil presser/Small scale oil press line |

| Above 30tpd | Pretreatment&solvent extraction+refinery |

Next, I will introduce the complete soybean oil pretreatment + soybean oil solvent extraction plant + soybean oil refinery plant one by one.

Soybean oil pretreatment and pre-pressing plant:

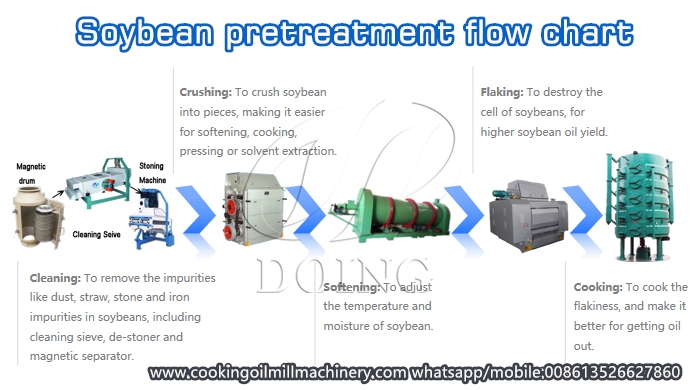

Pretreatment is to adjust the soybean into best state before pressing or solvent extraction, in order to increase oil output rate and improve oil and cake or meal quality.

The standard soybean pretreatment technology mainly includes cleaning, crushing, softening, flaking and cooking. Each steps has different functions. As the following picture shows:

Soybean pretreatment equipment and working flow chart

Soybean pretreatment equipment and working flow chart

After pretreatment, you can choose to press the soybean directly, using mechanical way to get crude soybean oil out, or send the cooked flakiness to solvent extraction plant for extracting more oil.

Types of soybean oil press machine

Types of soybean oil press machine

Soybean oil solvent extraction plant:

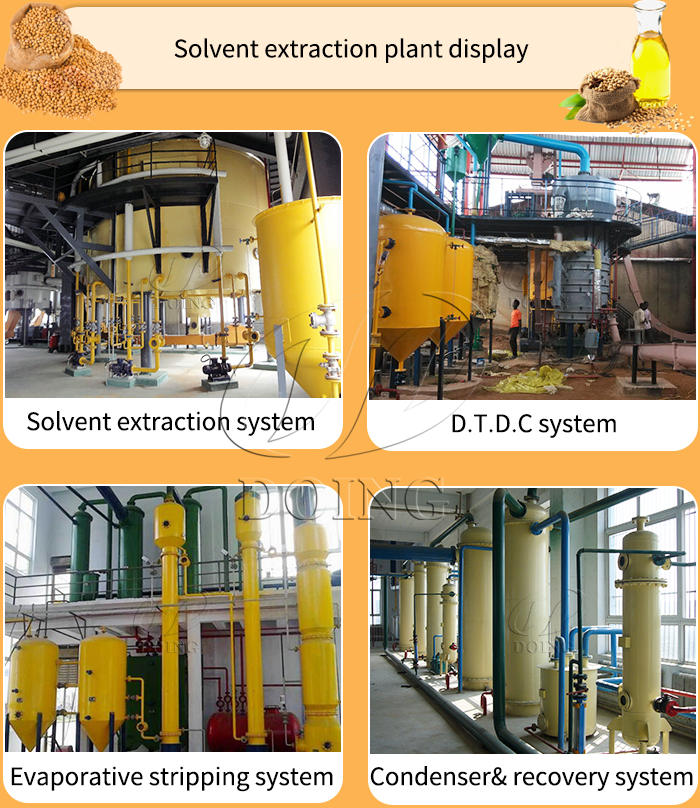

Solvent extraction is to use N-hexane to extract the oil from the processed oil seeds or cakes. The whole solvent extraction plant is anti-explosion considering of production safety. After solvent extraction, the oil residue is lower than 1%.

Since soybean oil that get from oil pressers is less, usually clients choose to add solvent extraction plant to get more soybean oil.

Soybean oil solvent extraction plant

Soybean oil solvent extraction plant

The solvent extractor first extract the crude soybean oil, then get two parts: miscella oil and the mixture of meal and solvents.

Through D.T.D.C system and miscella oil evaporation system, the solvent was separated from oil and meal. At last, condensate the gas state solvent into liquid state, and recover it for recycling use.

Soybean oil refinery plant:

No matter after pressing or solvent extraction, the soybean oil you get is crude soybean oil. Only after refining can it be edible oil. Henan Doing Company's soybean oil refinery plant has three types according to different capacities and clients' requirements for final product oil.

The three types of soybean oil refinery plant

The three types of soybean oil refinery plant

Soybean oil refining process includes degumming, deacidification, decolorization/bleaching and deodorization. Through these process, the gums, acid, pigment and bad smell in the crude oil are all removed.

The detailed soybean oil processing plant project program and quotation, please contact DOING directly.

Related product recommend

Leave a message

If you wanna to get more details about High quality soybean oil processing machine, soybean oil refinery plant for sale with fractory price, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.