Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

What is dewaxing process during vegetable oil refinery?

Dewaxing process during vegetable oil refinery is to remove the wax content in some kinds of crude vegetable oil, such as sunflower oil, rice bran oil, cottonseed oil and corn germ oil. Because of high wax content, the quality and flavour of the refined vegetable oil will be influenced. And the presence of wax makes the oil appear cloudy at room temperature. But after dewaxing, the vegetable oil remains clear after 24h of storage at 0˚C.

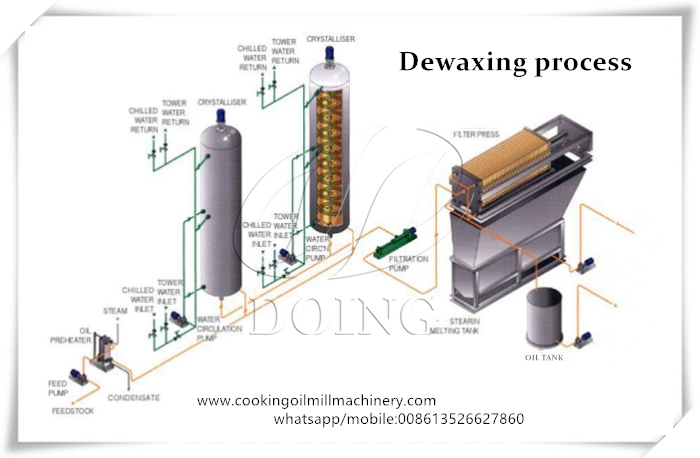

Dewaxing process 3d picture

Dewaxing process 3d picture

So dewaxing process is also called winterization. Henan Doing Company adopts the way of refining first and dewaxing last. So the crude vegetable should be refined in crude vegetable oil refinery plant, and then be pumped into dewaxing workshop. Dewaxing process during vegetable oil refinery has three main steps.

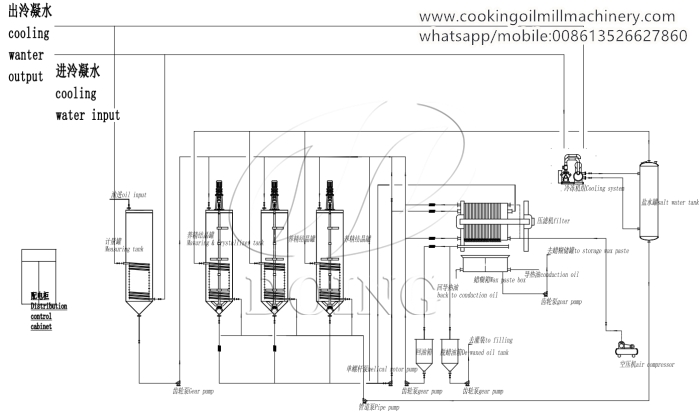

Dewaxing process flow chart

Dewaxing process flow chart

1. First, the refined vegetable oil should be heated to 55˚C, which is to make sure that all the crystal in vegetable oil have been broken.

2. Second, the vegetable oil is cooled slowly to 7–8˚C. In cooling process, new crystal come into being gradually. This process will sustain for 12-24h.

3. At last, after finishing the crystallization, vegetable oil will be pumped into filter machine to separate the wax from vegetable oil.

After dewaxing, the clarity and brightness of vegetable oil are both qualified the national standards. Generally, our customer will buy the sunflower oil refinery plant and sunflower oil dewaxing plant together, in order to get high quality sunflower oil. Henan Doing Company is a professional vegetable oil refinery machine manufacturer. Any question about vegetable oil refining, dewaxing and fractionation, our engineers can give you professional suggestion. Welcome to contact us!

PREV:How to start vegetable oil production business?

PREV:How to start vegetable oil production business?

NEXT:How much is the price of 5 tons per day small scale groundnut oil making machine?

NEXT:How much is the price of 5 tons per day small scale groundnut oil making machine?

Leave a message

If you wanna to get more details about What is dewaxing process during vegetable oil refinery?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.