Blog

- What is the complete process to make peanut oil, from raw peanuts to bottled oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Liberian client expands into palm oil extraction with small machines purchase from Henan Glory Company

- Henan Glory replenishes Nigerian overseas warehouse with palm oil & kernel making equipment

- A Cameroonian customer successfully booked a small palm oil pressing line

- Deal closed: YZYX70WZ sunflower oil press order for Cuban client

- A Nigerian customer successfully ordered 1tph palm fruit oil milling machines

How existing palm oil mills can process kernel oil efficiently?

How do you deal with your palm kernels, selling them at low prices or process them by yourself? If you selling them directly, it is a pity because palm kernel oil has a wide range of industrial and food applications. Therefore, Henan Glory recommend you add palm kernel oil processing plant in your existing palm oil mill for extra profit.

What Equipment I Need for Palm Kernel Oil Processing?

Henan Glory has 5-30 t/d palm kernel oil processing line which can help you process palm kernel oil efficiently.

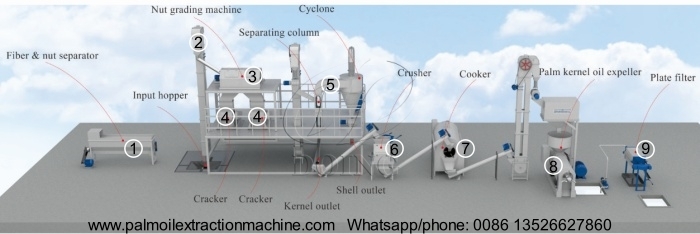

Small scale palm kernel oil processing line

Small scale palm kernel oil processing line

1. Fiber Separating Machine: This machine is used to separate the mixture of fiber and palm nuts.

2. Magnetic Separator: It is used to remove metal impurities adhered to the surface of palm nuts.

3. Nut Grading Screen: It is used to sort palm nuts by size to improve shelling rate.

4. Palm Nut Cracker: This machine is designed to break the hard shell of the palm nut to release the kernel inside.

5. Kernel and Shell Separator: After cracking, the kernels need to be separated from the shell by using an air separator or a vibration separator.

6. Palm Kernel Crusher: The palm kernels must be crushed to reduce their size, making it easier to extract oil.

7. Palm Kernel Conditioning: The roaster is used to soften the kernels before pressing, regulating temperature and moisture and improving oil yield.

8. Palm Kernel Oil Press Machine: Our Henan Glory Company, has upgraded the palm kernel oil press machine, using a screw made of a special material, which improves the pressing effect and lasts longer.

9. Plate Filter: The filter removes impurities from oil, further cleaning the extracted PKO.

How These Equipment Is Working Efficiently for My Palm Kernel Oil Processing Plant?

This video is our 3D animation which show you the whole working processing of palm kernel oil processing plant. You can see the palm nuts to be removed fibers, sorted and break, the kernel and shell to be separated, the kernel to be crushed, cooked, pressed and the kernel oil to be filtered. The whole process is with high efficiency, especially the palm kernel and shell separating system can improve the kernel and shell separating efficiency a lot.

Do you want to set up your own palm kernel oil processing plant? Let us give you best solutions! Contact us to begin your bespoke journey for your new project!

PREV:The anatomy of a commercial palm oil press machine

PREV:The anatomy of a commercial palm oil press machine

NEXT:Five major services that palm kernel oil processing equipment suppliers must provide

NEXT:Five major services that palm kernel oil processing equipment suppliers must provide

Leave a message

If you wanna to get more details about How existing palm oil mills can process kernel oil efficiently?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line