Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

How to remove the solvent left in the extracted oil?

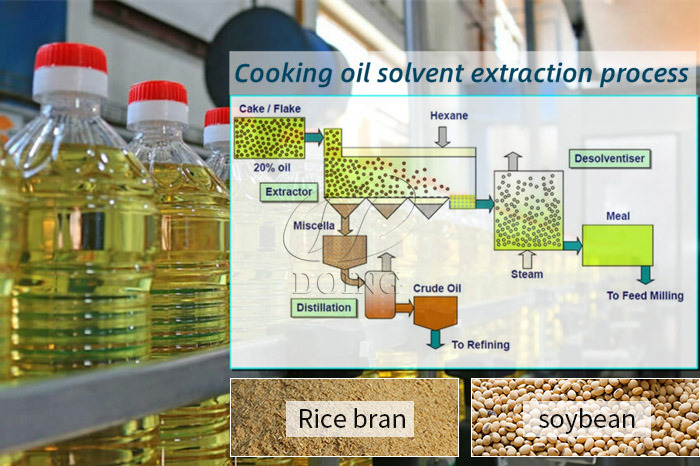

For large-scale soybeans and rice bran, we usually use solvent extraction to extract soybean oil and rice bran oil. Solvent extraction uses the mutual solubility of chemical solvents and oils to extract the oil from the raw materials. Then, how to remove the solvent left in the extracted oil?

Solvent extraction machine

Solvent extraction machine

The solvent extraction of edible oil is mainly divided into four sections: solvent extraction section, mixed oil stripping section, wet meal precipitation section and solvent condensation recovery section. We introduce from the process flow of solvent extraction method, how the residual solvent in the extracted oil is removed in different stages of solvent extraction.

Process flow of solvent extraction method

Process flow of solvent extraction method

The first is the solvent extraction section. Put the pretreated oil cake into the extractor, and spray n-hexane solvent on the oil cake through the nozzle, so that the solvent is fully mixed with the oil cake in the extractor, and the oil in the oil cake is dissolved in the solvent to obtain a mixture of solvent and oil , called mixed oil.

Then there is the mixed oil stripping section. After the mixed oil obtained in the first stage enters this stage, the solvent and the oil are separated by the evaporator under high temperature and negative pressure by utilizing the difference in boiling point between the solvent and the oil. At this stage, most of the solvent in the extracted oil is removed, and the separated oil can be temporarily stored for refining after filtration.

In the wet meal desolventization section, the extracted oil cake is mainly steamed and fried through the steam line, and the solvent in the cake is evaporated into solvent vapor, which enters the solvent condensation recovery section. The oil cake obtained in this process can also be mixed with solvent for secondary extraction to obtain more oil.

Solvent condensation recovery is mainly used to cool the solvent in the miscella stripping section and wet meal desolventization section, so that the solvent becomes liquid and returns to the leaching section for reuse. This minimizes solvent loss and saves even more costs.(Recommend reading: Soybean oil processing plant)

Solvent extraction plant

Solvent extraction plant

After the above four stages, most of the solvent in the extracted oil has been removed, but if you want to completely remove the solvent in the extracted oil to obtain edible refined oil, you need to equip edible oil refining equipment. Henan Glory Company can provide you with edible oil pressing equipment, edible oil solvent extraction equipment, edible oil refining equipment, etc. Welcome to contact us.

Leave a message

If you wanna to get more details about How to remove the solvent left in the extracted oil?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.