Blog

- Modular Palm Fruit Oil Processing Machine Solution

- From Pressing to Refined Oil: Adding Profitable Edible Oil Refining Lines to Your Current Facility

- What is mechanical extraction of soybean oil?

- What Kind of Engineering Service Can Henan Glory Offer in Cooking Oil Processing Project?

- The Anatomy of a Commercial Palm Oil Press Machine

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory Ships Palm Fruit Processing Machines to Indonesia in One Month

- Purchase Deal Finalized Between Nigerian Loyal Customer and Henan Glory on Palm Fruit Debunchers

- Delivery Update: 1TPH Palm Oil Extraction Machines Order Ready to Ship to Nigeria

- Nigerian Long-Term Client Signs Repeat Order for Palm Kernel Oil Processing Machines

- Henan Glory’s 1tph small palm oil processors successfully ordered by Nigerian client

What is the sunflower oil production process?

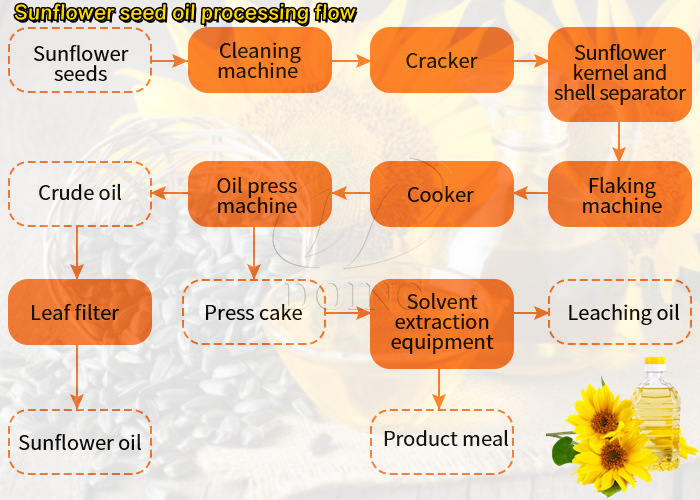

Sunflower oil is a common vegetable oil that is extracted from sunflower seeds. The production process of sunflower oil includes multiple steps such as cleaning, shelling, kernel shell separation, cooking, pressing, filtering, and refining. Let's take a closer look at the production process of sunflower oil.

Sunflower oil production process

Sunflower oil production process

Step 1: Clean Up

After the sunflower seeds are picked, the equipment needs to be cleaned to remove impurities and dirt. Generally, we use special cleaning equipment, such as vibrating screens, stone removers and magnetic separators. Vibrating screens can remove light impurities, such as leaves, etc., and stone removers are mainly used to remove stones, clods, etc. Finally, a magnetic separator is used to absorb impurities such as iron blocks, so that we can get cleaner sunflower seeds.

Step 2: Shelling and kernel shell separation

Since sunflower seed hulls will reduce the oil yield, we first use a sheller to shell sunflower seeds to obtain sunflower seed hulls and sunflower kernels, and then use a kernel shell separator to separate the sunflower seed hulls and sunflower kernels to obtain sunflowers seeds.

Step 3: Cooking

Then, we use the cooker to adjust the temperature and humidity of the sunflower seeds, so that the sunflower seeds are in the best pressing conditions and improve the oil yield of sunflower oil.

Step 4: Press

The cooked sunflower seeds need to be pressed to extract the oil. The pressing method can be cold pressing or hot pressing. The method of cold pressing is to put the sunflower seeds in a press, and through mechanical pressing, the oil is pressed out of the sunflower seeds. Hot pressing is based on cold pressing, heating sunflower seeds to make it easier to squeeze out the oil.

Sunflower oil press

Sunflower oil press

Step 5: Filter

Pressed sunflower oil needs to be filtered to remove impurities and residues from the oil. The filtering method can be physical filtering. The method of physical filtration is to use a plate and frame filter to filter out the moisture and impurities in the oil.

Step 6: Refining

Pressed sunflower oil is refined to remove odors and impurities from the oil. Refining generally adopts the method of chemical refining, absorbing the odor and impurities in sunflower oil to the adsorbent, and then separating the adsorbent and odor impurities through filtration. (Recommned reading: Sunflower oil processing plant)

The above is the production process of sunflower oil. If you want to develop sunflower oil processing business, please contact Henan Glory Company, we can provide you with professional sunflower oil processing machine.

PREV:What is the working principle of cooking oil press? is it safe?

PREV:What is the working principle of cooking oil press? is it safe?

NEXT:How to extract oil from rice bran? What equipment is needed?

NEXT:How to extract oil from rice bran? What equipment is needed?

Leave a message

If you wanna to get more details about What is the sunflower oil production process?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.