Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

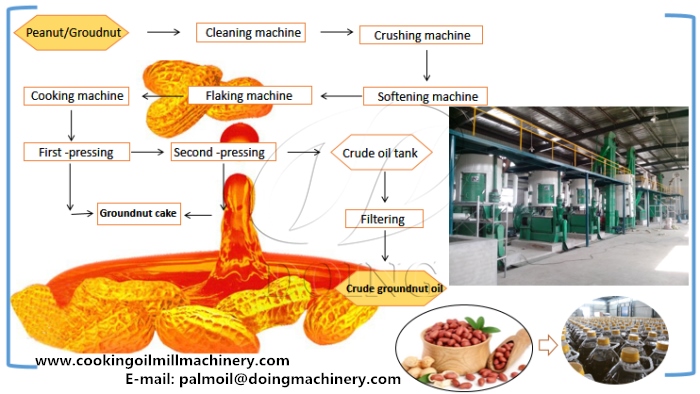

What is the extraction process of peanut oil?

The extraction process of peanut oil varies slightly according to the amount of peanut oil processed. Here we take the extraction process of large peanut oil production line as an example to introduce.The extraction process of peanut oil consists of six steps, respectively: cleaning, shelling, crushing, flaking, steaming and frying, pressing.

The extraction process of peanut oil

The extraction process of peanut oil

The first step:Cleaning

As an oil plant, peanuts inevitably carry some impurities.If the soil, stems and leaves buried in peanuts are not removed, it will not only affect the quality of oil and cake, but also reduce the oil yield.There are many ways to clean up, depending on the impurities.If the impurities are light, such as grass, stems, leaves, etc., vibrating screen can be used to screening the impurities from peanuts.If it is soil, it can be removed by stone-removing machine according to the density.If the impurity is iron, an electromagnet or permanent magnet can be used for magnetic separation.

Peanut oil cleaning equipment

Peanut oil cleaning equipment

The second step:Shelling

The purpose of shelling is to reduce the shell of oil adsorption, speed up the rate of oil. It can speed up the processing capacity of peanut oil press and reduce the wear of oil press equipment; Conducive to rolling billet, speed up the quality of crude oil. It can quicken the quality of cake and be beneficial to comprehensive utilization.

The third step: Crushing

The crusher will be used in the process of peanut crushing, the purpose of crushing is to make the particle size of crushed peanuts meet the conditions of flaking.

The fourth step: Flaking

Flaking refers to using a single pair of roller rolling machine rolling into thin and uniform billet. By rolling the embryo, on the one hand, part of peanut oil is rolled out from the peanut in advance to reduce the pressure of the press , on the other hand, the oil yield of the whole peanut oil extraction process is improved.

The fifth step: Steaming and frying

Steaming and frying destroy the cell structure of oil, denaturate protein, absorb water and expand phospholipid, meet the requirements of pressing, speed up oil production and reduce the content of phospholipid. The effect of steaming and frying directly affects the smooth progress of the whole oil production process, the level of oil yield and the quality of oil products and cakes.

The photo of peanut roaster machine

The photo of peanut roaster machine

The sixth step: Pressing

In the pressing stage of peanut oil, we most commonly used is the screw press, it has simple structure, high pressure, can continue to process materials, low labor intensity, can press a variety of oil such as groundnut, soybean, palm kernel, cottonseeds, sesame seeds, castor seeds, etc..

The peanut oil screw press

The peanut oil screw press

From the above introduction, you should have a general understanding of the extraction process of peanut oil. Henan Glory Company offer customized plan for every customers to help them establish their own business in edible oil processing factory. If you are interested in, just get in touch with us, our technical engineers together with sales will try the best to offer the most suitable oil production plan based on your budget and requirements!

Leave a message

If you wanna to get more details about What is the extraction process of peanut oil?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.