Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Deal closed: YZYX70WZ sunflower oil press order for Cuban client

- A Nigerian customer successfully ordered 1tph palm fruit oil milling machines

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

What is the solvent extraction process of soybean oil?

The solvent extraction process of soybean oil refers to select some organic solvent that can dissolve soybean oil, through contact with oil (soaking or spraying), the soybean oil in soybean cake is extracted.

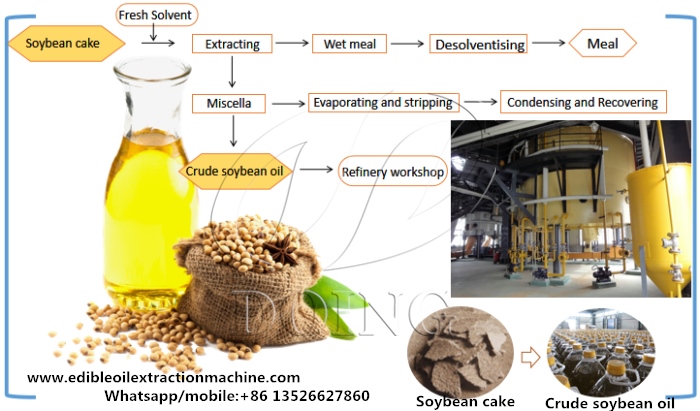

The solvent extraction process of soybean oil is divided into four sections: solvent extraction section, wet meal desolvation section, mixed oil evaporation and stripping section and solvent recovery section.

Soybean oil solvent extraction process flow chart

Soybean oil solvent extraction process flow chart

Solvent extraction section is dip soybean oil embryo or squeeze the soybean bake in the selected solvent to dissolve grease in dissolving agent,and then separate the mixed oil from solid residue. Solvent extraction section is the most basic step in solvent extraction process,in this section,we can get the wet meal and mix oil.

Solvent extraction part of soybean oil solvent extraction workshop

Solvent extraction part of soybean oil solvent extraction workshop

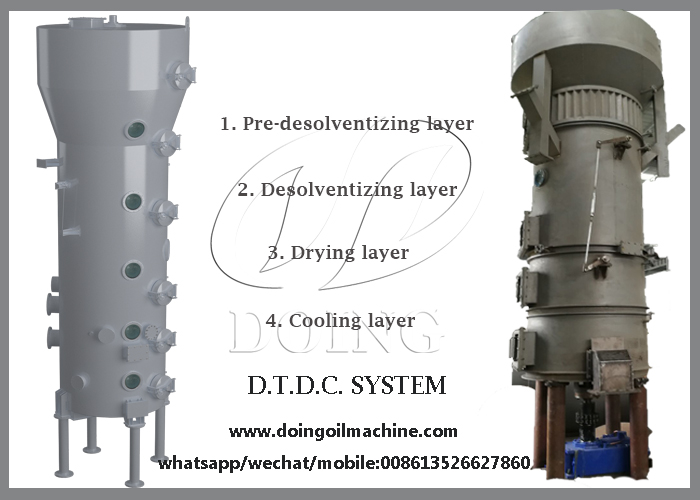

The wet meal desolvation section refers to the process of processing the wet meal obtained from the extractor. Wet meals are discharged from the bottom of extractor, enter from the top of D.T.D.C and land on the pre-desolventizing trayer. On the pre-desolventizing trayer, wet meals are heated by the steam directly. Next, pre-desolventized meals land on the next pre-desolventizing trayer where the pre-desolventized meals are heated by the steam again. After Desolventizing, the meals land on the following drying and cooling layer. After drying and cooling meals, dry meals are sent into meal storehouse.

D.T.D.C. system

D.T.D.C. system

Mixed oil evaporation and stripping section refers to the process of processing the mix oil obtained from the extractor. The principle of mixed oil evaporation and stripping system is to use the difference between the boiling points of the solvent and oil to evaporate and strip the miscella. After this process, we can get pure crude soybean oil.

Finally, solvent recovery section refers to the process of recovery and reuse of solvent recovered from wet meal desolvation section and mixed oil evaporation and stripping section. During solvent recovery process, the equipment that we need to use is vertical tube condensation system.

In general, the extraction process of soybean oil has the characteristics of low residual oil rate in meal and high oil extraction rate, which can help us to obtain greater economic benefit. If you want to make more soybean oil from soybean oil processing business, soybean oil solvent extraction plant maybe a good choice, if you want to get more information about equipment, welcome to contact us.

Leave a message

If you wanna to get more details about What is the solvent extraction process of soybean oil?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line