Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

What are the production processes of groundnut oil?

Groundnut is one of the high oil content rate oil seed, and it is widely planted around the world, so the groundnut oil is also one of the most popular edible oil with consumers. If you want to start groundnut oil production business, it is very wise. And the production processes of groundnut oil is not very complicated, the machines used in the production processes of groundnut oil is also ordinary, similar with other oil seeds.

Generally speaking, the production processes of groundnut oil can be divided into two step: 1. extracting crude oil; 2. refining crude oil into product oil.

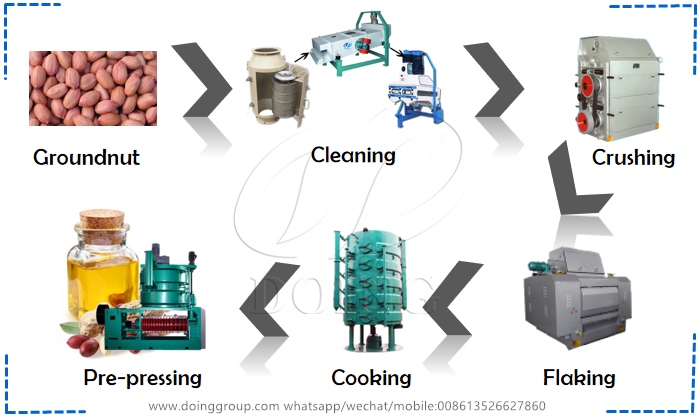

The production processes and machines of groundnut oil

The production processes and machines of groundnut oil

First step is to extract the crude oil out from groundnut kernel. If you groundnut is with shell, then first we need to use husker to remove shell, and using cleaning sieve, de-stoner and magnetic drum to remove impurities like straw, dust, stone and iron impurities in the groundnut. After that, we need to crush peanut into small pieces, in order to make it easier to get oil out. Then flake the pieces into flakiness. And cook it to adjust moisture and temperature.

As for extracting oil, we have two methods: one is pressing method, which is mechanical pressing directly, with around 7%-8% oil residue rate. The other is pre-pressing and solvent extraction method, which is to pre-press part of oil out first, then take groundnut cakes to solvent extraction, so that final oil residue is lower than 1%, which means you can get more oil.

The production processes in groundnut oil solvent extraction plant

The production processes in groundnut oil solvent extraction plant

If adopting mechanical pressing method, you will get crude oil and cake, and the crude oil can be edible directly without refining. If using solvent extraction method, then the crude oil must be refined then can be edible.

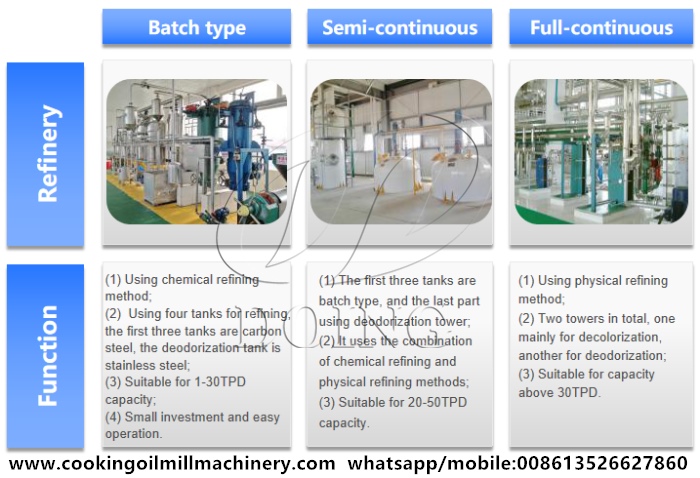

As for groundnut oil refinery, we have three types: batch type, semi-continuous and full continuous type. According to your requirement and budget, our engineers can recommend most suitable one for you.

Three types of groundnut oil refinery machine

Three types of groundnut oil refinery machine

The groundnut oil refining process consists of four steps: degumming, deacidification, decolorization and deodorization. After refining, the impurities in crude groundnut can be removed, such as gums, acid, pigment and bad smell, and you will get high quality product groundnut oil, which can be sold in the supermarket.

So, what final oil you want to get? You can send message to us, telling us your requirement, and our sales and engineers will recommend suitable machine for you to prduce groundnut oil.

Leave a message

If you wanna to get more details about What are the production processes of groundnut oil?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.