FAQ

Project Case

- 50TPD soybean oil puffing press production line in Nigeria

- 1TPD cottonseed oil refining machine ordered by our Ugandan customer has been installed

- 5TPD rapeseed oil processing production line successfully installed in Yunnan Province, China

- 5tph palm kernel cracker and separator project and 1tph palm kernel oil making machine project in Uganda

- Complete small scale edible oil production line project in China

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Nigerian customer purchased a 30tpd soybean oil pressing line from Henan Glory Company

- Good News: YZYX70 cooking oil press machine sold to customer in Malawi!

- Successful Partnership: Ghanaian Client Chose Henan Glory's Cooking Oil Press Machine

- Nigeria customer successfully ordered 500kg/h diesel engine powered palm oil press machine from Henan Glory company

- Henan Glory Company shipped 20tpd peanut oil production machines to Sudan

Rice bran oil processing plant

Rice bran oil processing plant

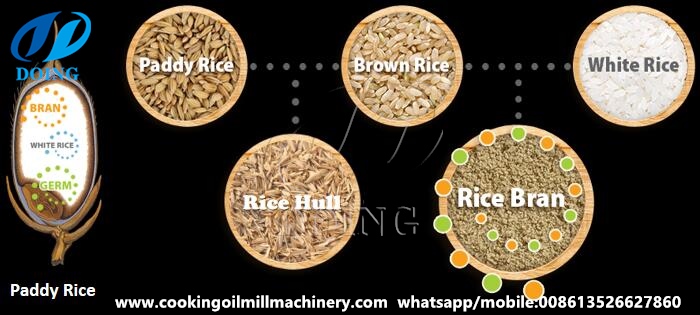

From paddy rice to rice bran and white rice

From paddy rice to rice bran and white rice

As the above picture shows rice bran is the hard brown outer layer of white rice. 100kg brown rice can get 5-8kg rice bran. Rice bran is a mixture of substances, including protein, fat, ash, and crude fiber, inside which, the oil content in rice bran is 10−23%.

Rice bran and rice bran oil

Rice bran and rice bran oil

Rice bran oil is known for its high smoke point of 232 °C (450 °F) and mild flavor, making it suitable for high-temperature cooking methods such as stir frying and deep frying. It is popular as a cooking oil in several Asian countries, including Bangladesh, Japan, India, and China.

The features of rice bran oil extraction process:

1. The processing capacity of rice bran oil processing plant

The oil content is very low in rice bran, and it is not economical for the owner if the capacity lower than 20tpd, considering the rice bran oil price, machine and factory cost. So Henan Doing Mechanical Equipment Co., Ltd provide the smallest capacity of rice bran oil processing plant is 20tpd, and the processing method is pretreatment & solvent extraction.

2. The processing method of rice bran oil

Why use pretreatment & solvent extraction method to produce rice bran oil? By this way, the oil residue in rice bran oil meal will be lower than 1%, and the meal is more suitable for animal food.

3. The storage characteristics of rice bran

It is better to build the rice bran oil processing plant near a rice mill plant. Because rice bran got from rice mill should be pretreated firstly to control the acid value not increase rapidly. In this way, rice bran can preserve 10-15 days. (Acid value is the most important factor of rice bran oil. )

The pretreatment of rice bran:

Rice bran --- Cleaning --- Moisture conditioning -- Puffing -- Drying -- Storaging

Rice bran pretreatment equipment and rice bran that has been puffed

Rice bran pretreatment equipment and rice bran that has been puffed

The rice bran oil solvent extraction plant:

After puffing, the rice bran can be preserved for about 10-15 days. During these time, the rice bran are sent to rice bran oil solvent extraction plant to produce rice bran oil.

Rice bran oil solvent extraction plant

Rice bran oil solvent extraction plant

Rice bran oil refining and dewaxing plant:

Rice bran oil refinery contains 5 sections: degumming, deacidification, decolorization deodorization and dewaxing. The types of rice bran oil refinery that Henan Doing Company manufactures as the following table shows.

| Types and Capacity | Brief Introduction |

|

|

Batch type, low cost, easy installation and small footprint. |

|

|

Degumming, deacidification and decolorization parts are batch type and deodorization part using fully continuous deodorizing tower. |

|

|

Full contunuous, no need much human operating. |

The detailed rice bran oil processing plant project program and quotation, please contact DOING directly.

Related product recommend

Leave a message

If you wanna to get more details about High quality rice bran oil processing machine, rice bran oil refinery plant for sale with fractory price, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

1-2-3-5-10tpd

1-2-3-5-10tpd 10-50tpd

10-50tpd Above 30tpd

Above 30tpd