Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

Project Case

- 2TPH Palm Oil Processing Plant in Nigeria

- 50TPD soybean oil puffing press production line in Nigeria

- 1TPD cottonseed oil refining machine ordered by our Ugandan customer has been installed

- 5TPD rapeseed oil processing production line successfully installed in Yunnan Province, China

- 5tph palm kernel cracker and separator project and 1tph palm kernel oil making machine project in Uganda

Oil press machine

Sunflower oil processing machine

- Product name: Sunflower oil processing machine

- Company type: Manufacturer, supplier & exporter

- Replytime: Within 24 hours

- Whatsapp/Mobile: 0086 13526627860

- Email: sales@doingoilmachine.com

Sunflower seeds are a popular source of oil, and the process of extracting oil from them involves several steps. Sunflower oil processing machine are essential for this process, and they include cleaning machines, husking machines, drying machines, flaking machines, cooking machines, and sunflower oil pressing machines. These machines are highly effective, automatic, and use mature technology. At Henan Doing Company, we can design a sunflower oil processing plant that meets your needs, whether it is a small-scale 5-10tpd sunflower oil processing plant or a large-scale 30-1000tpd sunflower oil pressing production line.

Sunflower oil pressing production line

Sunflower oil pressing production line

The oil content of sunflower seeds is between 40-60%, and the shells of sunflower seeds do not contain oil. Therefore, large-scale sunflower oil processing plants must have husking machines and kernel and shell separating machines. However, if your sunflower oil processing plant is small-scale, you can choose to press the sunflower seeds with shells. Our engineers can design the most suitable sunflower seed pretreatment and pressing process for each customer based on their specific needs.

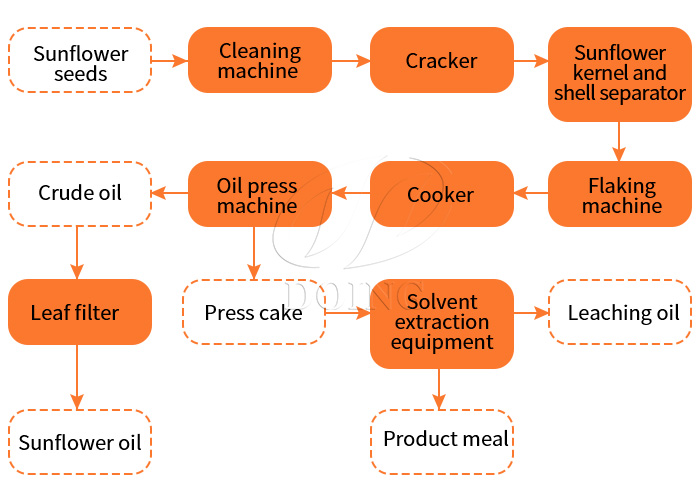

The usual sunflower seeds pretreatment process is as follows:

Sunflower seeds pretreatment process

Sunflower seeds pretreatment process

The sunflower seed pretreatment process is crucial in improving the quality of sunflower oil and ensuring that most of the oil is extracted from the seeds. The process involves several steps, including:

1) Magnetic drum: The first step is to move the iron in the sunflower seed, because the iron will be harmful to the following sunflower oil processing machine.

2) Cleaning sieve: After going through the cleaning sieve, the impurities in the sunflower seed will be cleaned.

3) Husking machine: The cleaned sunflower seeds are then passed through a husking machine to remove the shells. The hulling rate is typically around 90%.

4) Separator of shell and kernel: The shell and nut are separated using a separating sieve. The first step is pre-separating, which reduces the shell rate to less than 2%. The second step is precise separating, which reduces the shell rate to less than 0.5%.

5) Dryer: After separating the shell and nut, the nut is dried at a temperature of 60℃ until the water content is reduced to 8-9%.

6) Flaking machine: The sunflower seeds are passed through a flaking roller to reduce the thickness of the cake to about 0.5mm.

7) Cooker: The cooker helps to adjust the water content of the material to 6-5kg/cm³.

8) Sunflower oil pressing machine: The crude sunflower oil is pressed using an oil pressing machine. The solid impurities in the crude sunflower oil are then removed to obtain clean oil.

After pressing, the sunflower cakes can also be extracted using solvent extraction, and the crude sunflower oil can be refined to obtain the best quality oil. If you are interested in setting up a sunflower oil processing plant, please contact us at Henan Doing Company.

Leave a message

If you wanna to get more details about Sunflower oil processing machine, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.