Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

How long does it take to set up a Groundnut Oil Processing Plant?

As the most common cooking oil, groundnut oil contains phospholipids, vitamins, choline and other substances beneficial to the human body, which can prevent skin aging, improve human brain memory, delay brain function decline and many other benefits. Therefore, more and more people want to invest in groundnut oil production business, so they ask Henan Glory Company: How long does it take to build a groundnut oil processing plant? Here, Henan Glory Company will provide you with reference through the following analysis.

The area and construction time of the groundnut oil processing plant depends on the customer's processing capacity. Here I will introduce three options for customers to choose from.

Option 1: If the customer has a limited budget and a small processing capacity, for example, only about 1-20 tons of raw materials need to be processed every day, one groundnut oil press can meet the customer's needs. In this case, the establishment of the plant is very fast, and only a vacant lot is needed, and the oil press is installed and ready for operation.

Different types of groundnut oil presses

Different types of groundnut oil presses

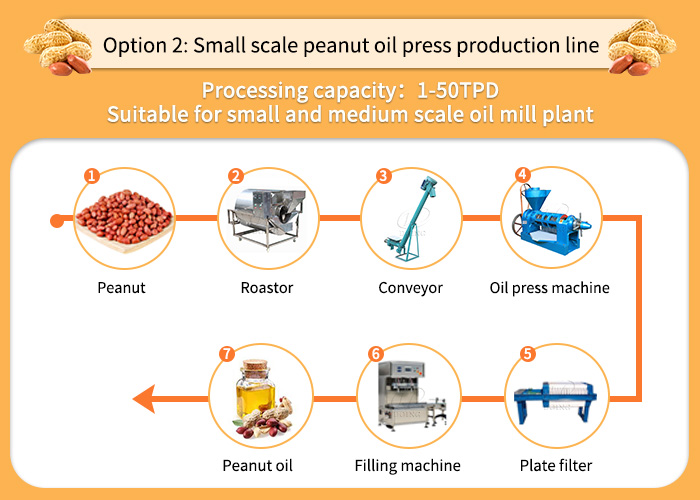

Option 2: If the customer has a sufficient budget and a processing capacity of 1-50 tons per day, and wants to obtain higher quality groundnut oil, then the customer needs a certain space to accommodate a small scale groundnut oil production line. The equipment included in the small scale groundnut oil production line mainly includes: roastor, conveyor, oil press, filter, filling machine, etc. However, the small scale groundnut oil production line is simple to install, and it can be completed in less than a week from the construction of the plant to the operation.

Small scale groundnut oil production line

Small scale groundnut oil production line

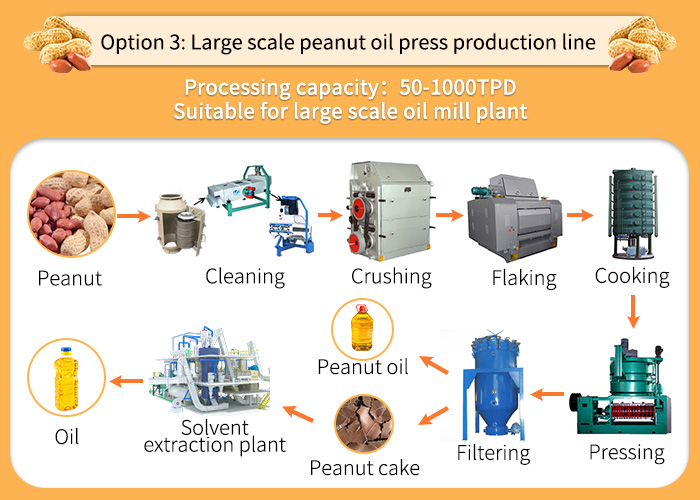

Option 3: When the customer's processing capacity is 50-1000 tons per day, it is necessary to build a medium and large scale groundnut oil processing plant, and a complete set of equipment is required to ensure the oil yield. For example, cleaning equipment is used to clean soil, stone and metal from raw materials; the flaking machine will eventually roll the groundnuts into flakes, thereby increasing the oil yield. The cooker is used to adjust the temperature and moisture of the groundnuts prior to pressing, so that they reach optimal pressing conditions. After pressing, there are filters to remove impurities and moisture from the oil. The plant construction plan is relatively time-consuming, but once completed, due to the high oil yield of the large scale groundnut oil production line, considerable profits will soon be obtained.

Large scale groundnut oil production line

Large scale groundnut oil production line

Henan Glory Company is a professional supplier of cooking oil production equipment. If you are interested in the production of groundnut oil, soybean oil, sunflower oil, etc., please contact us and you will get a free quotation and production plan.

PREV:Where can I buy sunflower and soybean oil press?

PREV:Where can I buy sunflower and soybean oil press?

NEXT:What are the purchasing options for groundnut oil processing machine?

NEXT:What are the purchasing options for groundnut oil processing machine?

Leave a message

If you wanna to get more details about How long does it take to set up a Groundnut Oil Processing Plant?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.