Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

How to control cooking oil refinery plant cost?

Running a profitable cooking oil refinery plant requires smart cost management without compromising quality. Effectively managing cost is critical for maintaining profitability and competitiveness in the cooking oil industry. Here are methods to control cost while maintaining high standards in your cooking oil refinery plant.

1. Choose the Right Cooking Oil Refinery Technology

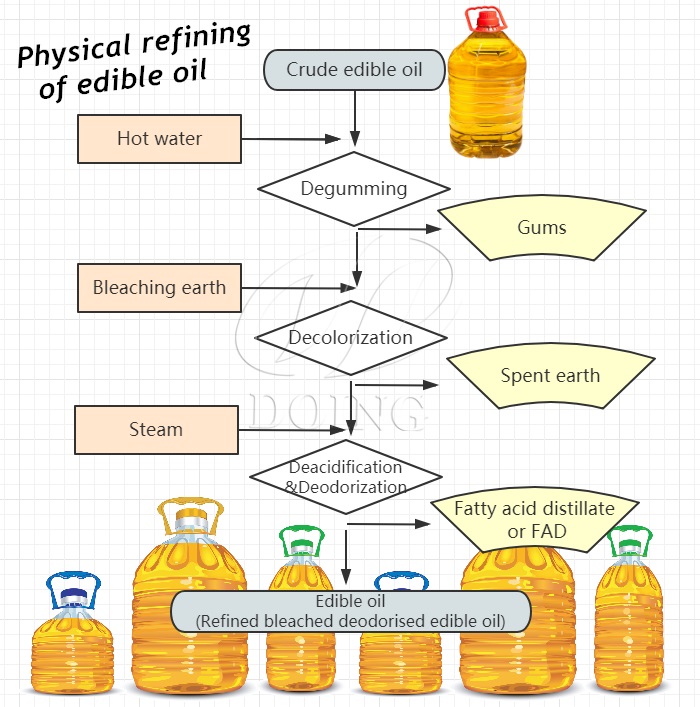

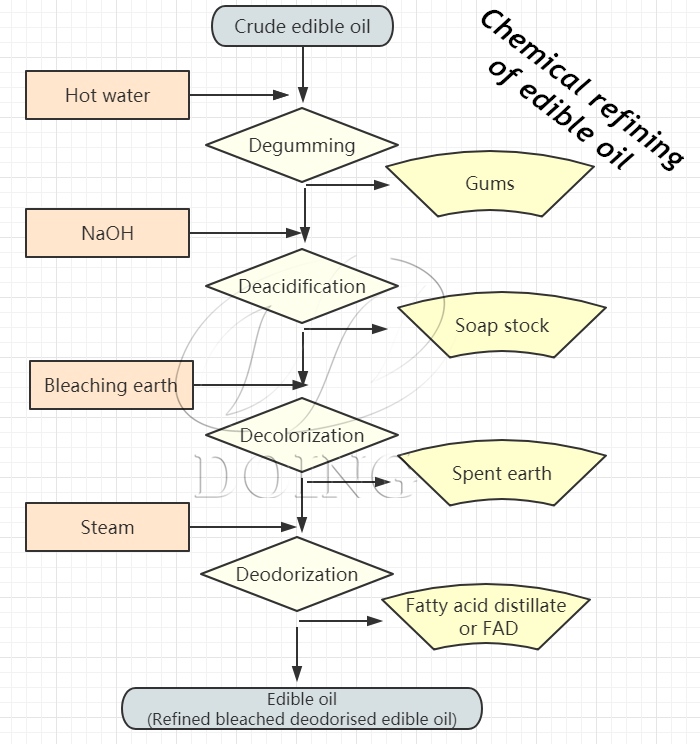

Taking Henan Glory Company as an example, we can provide you with two cooking oil refinery processes: physical refining and chemical refining. The differences between the two are as follows:

(1) Physical refining: It is more suitable for processing oils with high free fatty acid (FFA) content (such as palm oil, palm kernel oil, coconut oil, etc.). Its core advantage is the efficient and low-cost removal of FFA, and less wastewater. However, the degumming and decolorization of oils is very strict to ensure the stability, color and flavor of the final oils, and the removal effect of phospholipids, metal ions, etc. is not as thorough as chemical refining.

Physical refining of cooking oil

Physical refining of cooking oil

(2) Chemical refining: It has a wider adaptability to oil raw materials, especially good at processing oils with high phospholipid content (such as soybean oil, rapeseed oil, corn oil, sunflower oil, etc.). It can effectively remove phospholipids, free fatty acids, pigments and some trace metals at the same time. For oils with medium and low FFA content, chemical refining is a very mature and reliable method. However, for oils with extremely high FFA, the oil loss will increase significantly, and the cost-effectiveness will decrease.

Chemical refining of cooking oil

Chemical refining of cooking oil

2. Optimize Energy Consumption

(1) Use heat exchangers to recover and reuse thermal energy.

(2) Invest in energy-efficient boilers and steam systems.

(3) Consider biomass or waste-based fuels to reduce power expenses.

3. Reduce Chemical & Water Usage

(1) Implement closed-loop water systems to minimize waste.

(2) Optimize bleaching earth and phosphoric acid usage with automated dosing systems.

(3) Reuse filtered wash water to cut costs.

4. Improve Oil Yield & Minimize Losses

(1) High-efficiency degumming, deacidification, decolorization and deodorization reduce cooking oil losses.

(2) Advanced filtration systems ensure maximum oil recovery.

(3) Monitor FFA levels to prevent excessive refining losses.

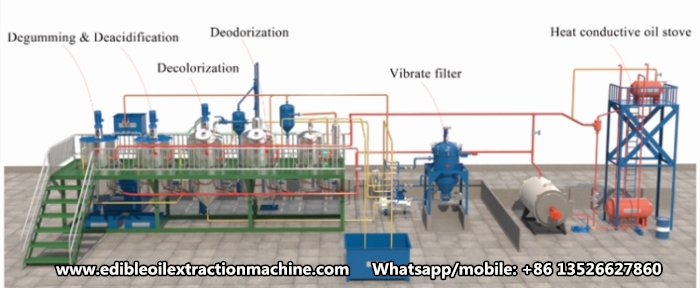

Cooking oil refinery equipment

Cooking oil refinery equipment

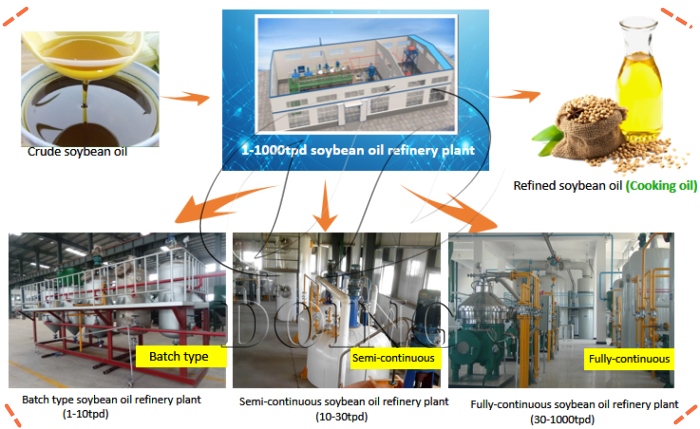

5. Smart Cooking Oil Refinery Equipment Selection & Maintenance

(1) Choose durable, low-maintenance cooking oil refinery equipment to avoid frequent repairs. In this regard, I recommend you the cooking oil refinery equipment of Henan Glory Company, which can be divided into 1-20 t/d batch type cooking oil refinery equipment, 10-50 t/d semi-continuous cooking oil refinery equipment and 30-1000 t/d fully continuous cooking oil refinery equipment. In addition, they can customize cooking oil refinery equipment according to the actual needs of customers to refine different types of edible crude oils, such as soybean oil, peanut oil, sunflower oil, etc.

(2) Schedule preventive maintenance to extend cooking oil refinery equipment lifespan.

(3) Invest in automation to reduce labor dependency.

Low-maintenance cooking oil refinery equipment

Low-maintenance cooking oil refinery equipment

6. Source Raw Materials Strategically

(1) Buy crude cooking oil in bulk during low-price seasons.

(2) Partner with local suppliers to cut transportation costs.

(3) Test oil quality before purchase to avoid refining penalties.

7. Reduce Waste & Byproduct Losses

(1) Sell soapstock, acid oil, and gums to recover costs.

(2) Use spent bleaching earth for alternative applications (e.g., brick manufacturing).

(3) Upcycle Lower-Grade Oils: Process lower-quality oils into industrial lubricants or biofuels instead of discarding them.

These are some method to control cooking oil refinery plant cost. By leveraging technology, optimizing processes and monetizing byproducts, cooking oil refinery plant can significantly reduce costs while maintaining product quality. Want to get cost-effective cooking oil refinery solutions now? Contact the Henan Glory Company(with branch and overseas warehouse in Nigeria) today!

PREV:Troubleshooting common peanut oil expeller problems

PREV:Troubleshooting common peanut oil expeller problems

NEXT:How to set up and running a small-scale cooking oil processing business?

NEXT:How to set up and running a small-scale cooking oil processing business?

Leave a message

If you wanna to get more details about How to control cooking oil refinery plant cost?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.