Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

What is the production process of cottonseed oil? What equipment is needed?

Cottonseed oil is the oil pressed from cotton seeds, is darker red in color than other oils. After refining, it can be eaten by humans. It contains a lot of essential fatty acids, and it is best mixed with animal fat for consumption. So what is the production process of the cottonseed oil? What equipment is needed?

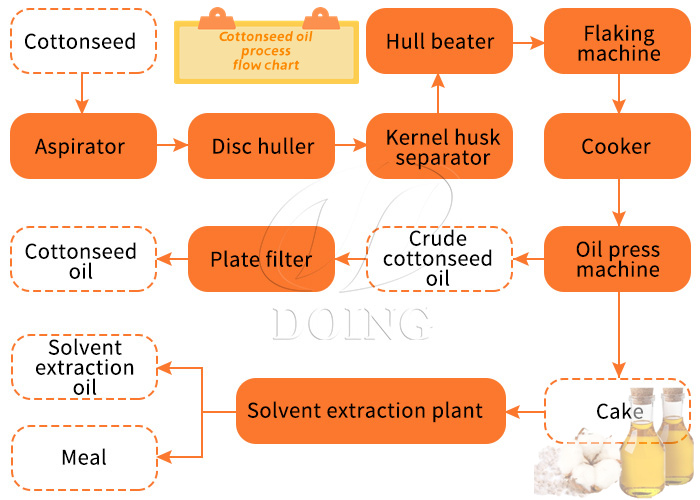

Cottonseed oil production process

Cottonseed oil production process

Before pressing we need to process the raw material, which consists of many steps. The first is to clean up the seeds, generally we will use different equipment to clean up different impurities. Firstly, disc huller is used to clean up the light impurities, then, hull beater is used to clean up the metal impurities in the raw materials to prevent damage to the equipment in the subsequent production process, we will then have clean seeds.

Secondly, these clean cottonseed will be processed by the cracker in small pieces, which is to increase the oil yield and at the same time reduce the production pressure of the subsequent equipment. At this point we will get a mixture of shells and kernels and will need a kernel-shell separation system to extract the kernels from the mixture. The next step is to roll the raw material, which is pressed into small piece to improve the oil yield. The next step is the cook the seeds, which aims to bring the temperature and humidity of the seeds to the optimum before pressing to increase the oil yield. It is a very important step before the pressing. We use the vertical steam cooker, which has several layers for better results. According to the customer's demand, we also configure an auxiliary cooker above the oil press to ensure that the best conditions are maintained before the seeds enters the press.

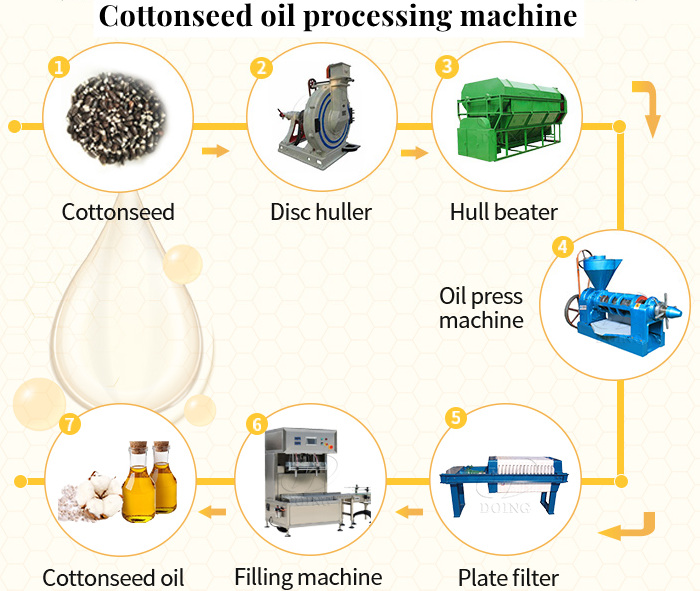

Cottonseed oil processing machine

Cottonseed oil processing machine

Next, the cooked cottonseed enters the oil press for pressing to obtain crude cottonseed oil. Each of our models of oil presses will be tested several times before leaving the factory. We can ensure easy operation, high oil yield, low failure rate and many other advantages. The next step is filtration, to remove the impurities from the crude oil. When we get the crude oil, we need to refine it to get the cooking oil. The refinery has 4 steps of degumming, deacidification, decolorization and deodorization. When we finish these 4 steps, we can get the cooking oil. And the production is complete finished. (Recommend reading: Cottonseed oil processing plant)

Our company is a technology-based manufacturing company under the umbrella of DOING Holdings, which integrates research and development, manufacturing, sales, installation and maintenance. If you have need about the cottonseed oil processing machine, please contact us.

PREV:Why does Henan Glory's edible oil press have a high oil yield?

PREV:Why does Henan Glory's edible oil press have a high oil yield?

NEXT:How much cost raised to build a 10 tons per day sunflower oil mill plant?

NEXT:How much cost raised to build a 10 tons per day sunflower oil mill plant?

Leave a message

If you wanna to get more details about What is the production process of cottonseed oil? What equipment is needed?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.