Blog

- Ultimate Guide to Palm Kernel Oil Processing Machines: Types & How They Work

- What is the working principle of crude palm kernel oil expeller?

- Batch Type Edible Oil Refining Machine 1TPD to 20TPD

- Must-Know Maintenance Tips for Your Soybean Oil Extraction Machine

- Crude Oil Refining Equipment: Key Machines & Their Roles

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- 2tph Drum-type Palm Fruit Threshing Machine: New Order Secured by Henan Doing Nig. Co.,Ltd from Nigeria

- Shipping Confirmation: Mini Palm Oil Processing Line Successfully Handed Over from Our Nigeria Branch

- Heading to Kenya! Henan Glory's Custom Sunflower Oil Extraction Equipment Is On the Move

- Shipment Update: Small Scale Palm Oil Mill Plants Successfully Shipped to Nigeria

- Tailored for 1TPD: Henan Glory Wins Nigerian Small Scale Palm Oil Production Equipment Order

How much cost raised to build a 10 tons per day sunflower oil mill plant?

For a sunflower seed factory that is scheduled to process 10 tons of sunflower seeds per day. Typically, the daily working hours are approximately 10-12 hours. The cost of constructing such a sunflower oil mill plant is mainly considered from two aspects, one is the construction of a production workshop, and the other is the procurement of sunflower oil processing machine.

Sunflower oil press machine

Sunflower oil press machine

For the construction cost of the production workshop, it is necessary to consult your local construction team to confirm the factory construction cost. At the same time, if you require, we can also provide technical support such as factory layout planning. The cost of sunflower oil processing machine varies from $32000 to $69500 depending on the equipment configuration.

For customers with low initial investment budgets, production equipment mainly includes transportation equipment, roaster, oil presses, and plate filters. These equipment can meet the most basic production needs. Roaster can adjust the moisture and temperature of raw materials to achieve the most suitable pressing state, greatly improving the oil yield. The oil press adopts a circular discharge oil press, which is more wear-resistant in design, has a longer service life, and is not easily damaged. The residual oil rate is about 6% - 7%. After obtaining the crude oil. In order to further improve the quality of edible oil storage time. We also added filtration equipment after the pressing section. Filtering through a filter cloth not only removes fine impurities in the edible oil, but also absorbs water from the crude oil.

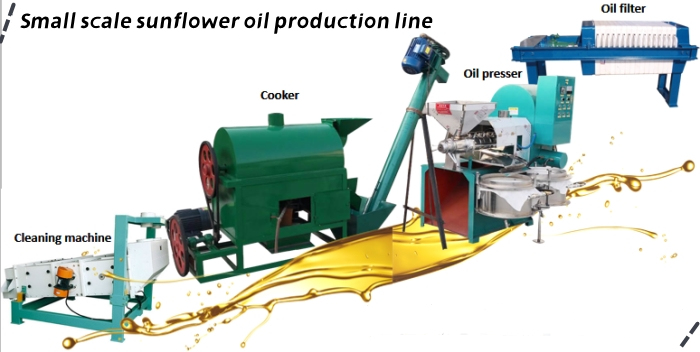

Small scale sunflower oil production line

Small scale sunflower oil production line

If the budget is sufficient, we will also configure cleaning equipment and crushing equipment before cooking raw materials. Cleaning the equipment and removing impurities from the raw materials through vibration screening not only make the raw materials cleaner, but also prevent impurities from entering the subsequent equipment, causing damage to the equipment. The crushing equipment removes part of the sunflower seed shell and crushes the sunflower seed kernel by peeling and crushing the raw material. This can increase the contact area between the oil press and the oil, further improving the oil yield. (Recommend reading: Sunflower oil processing plant)

Sunflower oil processing machine

Sunflower oil processing machine

If you are interested in the construction of sunflower oil mill plant, you can contact us at any time. We not only have sunflower oil processing machine, but also sunflower oil refining machine, sunflower oil dewaxing machine, and other equipment. And we have a professional team of engineers who can provide customized solutions based on your budget and needs.

PREV:What is the production process of cottonseed oil? What equipment is needed?

PREV:What is the production process of cottonseed oil? What equipment is needed?

NEXT:Different extraction methods of cooking oil: pressing and solvent extraction

NEXT:Different extraction methods of cooking oil: pressing and solvent extraction

Leave a message

If you wanna to get more details about How much cost raised to build a 10 tons per day sunflower oil mill plant?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.