Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

How to Ensure the Normal Operation of the Sunflower Oil Processing Machine?

Sunflower oil is widely used for cooking, making it a lucrative industry for producers. To maintain a consistent supply of high-quality oil, it is essential to ensure the normal operation of the sunflower oil processing machine. This article explores some key practices and maintenance tips to optimize the performance and longevity of the machinery.

1. Regular Cleaning and Lubrication:

Regular cleaning and lubrication of the processing machine are crucial to its smooth operation. Oilseed residues and dust can accumulate over time, leading to machine malfunctions. Clean all parts of the machine, such as feed hoppers, seed conveyors, and extraction systems, using appropriate cleaning agents. Additionally, ensure that all moving parts are properly lubricated to reduce friction and prevent wear and tear.

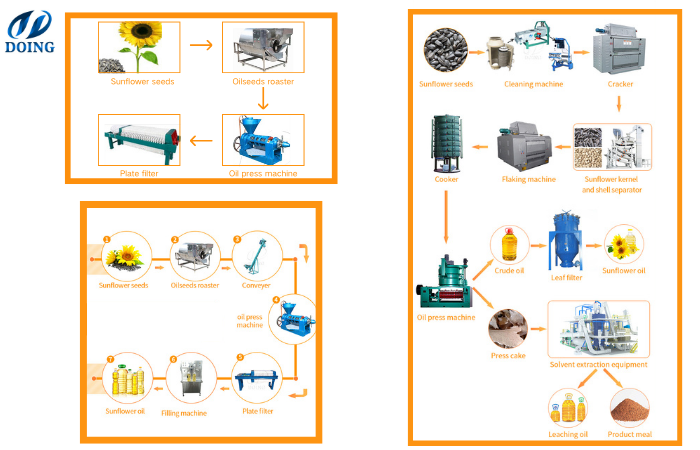

Sunflower oil processing machines

Sunflower oil processing machines

2. Inspect and Replace Worn-out Parts:

Regular inspections are essential to identify any worn-out or damaged parts that need immediate attention. Monitor components like belts, gears, pulleys, and bearings for signs of wear or damage. Replace them promptly to avoid unexpected breakdowns and minimize downtime. DOING company will configure corresponding wearing parts according to the customer's needs when purchasing our sunflower seed processing machine in the early stage. And the wearing parts will be shipped together with the sunflower seed oil processing machine.

3. Calibration and Adjustment:

A properly calibrated sunflower oil processing machine ensures accurate output and prevents unnecessary wastage. Pay attention to parameters such as temperature, pressure, and extraction rate to maintain optimum efficiency. Make necessary adjustments, such as altering feed rates, to adapt to different seed varieties or changing environmental conditions. Regularly monitor and adjust the settings for optimal performance.

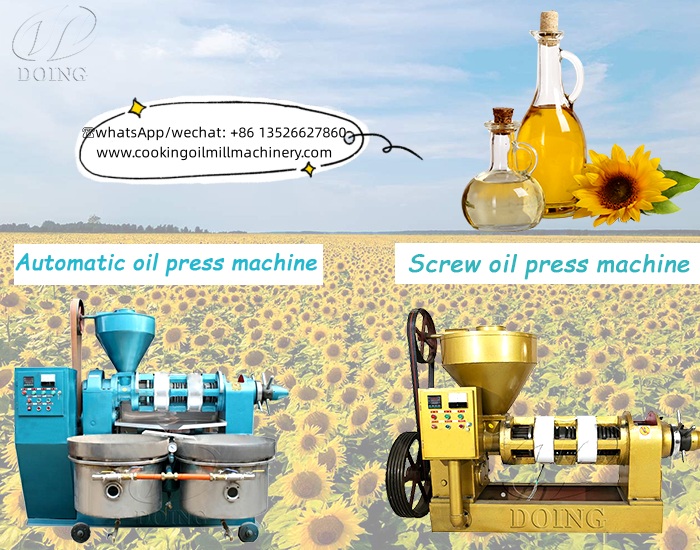

Automatic temperature control sunflower oil pressing machines

Automatic temperature control sunflower oil pressing machines

DOING company produces different sunflower oil pressing processing machines, including two types with automatic temperature control, which can automatically adjust the temperature, ensure that the loss of the machine is reduced, and can also increase the oil yield.

4. Operator Training:

Well-trained operators play a vital role in the smooth functioning of the processing machine. Conduct comprehensive training programs to educate operators about the machine's features, controls, and maintenance requirements. Train them to identify potential issues, troubleshoot problems, and conduct routine inspections. Well-informed operators can take appropriate actions promptly, minimizing the risk of significant breakdowns.

Training on the operation of sunflower oil processing machines

Training on the operation of sunflower oil processing machines

DOING company can provide free operating training for our customers. After the shipment or the installation, we usually provide training on the operation of sunflower oil processing machines for our customers online or on-site.

5. Preventive Maintenance Schedule:

Implementing a preventive maintenance schedule is essential to prevent major breakdowns and extend the machine's lifespan. Create a maintenance checklist specifying tasks such as cleaning, lubrication, parts inspection, and calibration. Follow the designated schedule strictly, ensuring all maintenance tasks are completed on time. Regular maintenance reduces the chances of unexpected failures and can save substantial costs in the long run.

In addition, the sunflower oil processing line machines provided by DOING Group are specially designed with a sunflower seed pre-treatment machines - a magnetic separator, which can effectively clean screws, metal and other impurities in sunflower seed raw materials, to avoid these metal impurities from causing damage to the sunflower oil processing machines.

Sunflower oil pre-treatment & processing machines

Sunflower oil pre-treatment & processing machines

The above is an introduction to the methods to ensure the normal operation of the sunflower oil processing machine. If you want to know more methods, please call us. We are a professional manufacturer and seller of sunflower oil processing machines. If you need to purchase a sunflower oil processing machine, please feel free to contact us. We will design a plan and provide you with a free quotation as soon as possible.

PREV:What are the sections of the cooking oil processing line?

PREV:What are the sections of the cooking oil processing line?

NEXT:How to improve the oil yield of the peanut oil pressing process?

NEXT:How to improve the oil yield of the peanut oil pressing process?

Leave a message

If you wanna to get more details about How to Ensure the Normal Operation of the Sunflower Oil Processing Machine?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.