Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

How to improve the oil yield of the peanut oil pressing process?

The peanut oil pressing process is a relatively common method of extracting peanut oil. How to maximize the oil yield of peanut oil in this pressing process? Involving the following aspects, choose good peanuts, pre-treatment of peanuts, choose good peanut oil pressing machines. The following is a detailed introduction to you:

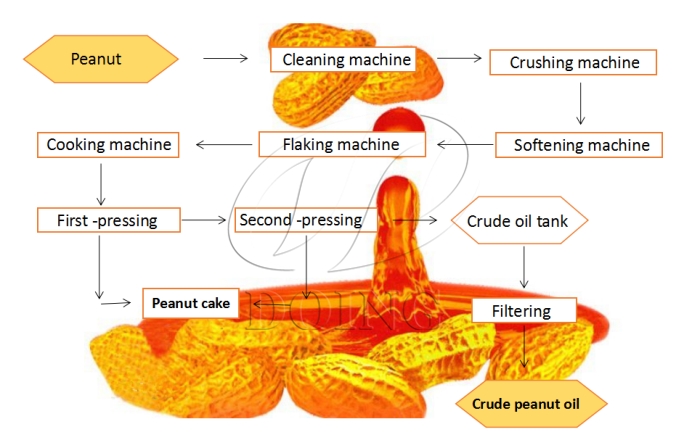

The peanut oil pressing process

The peanut oil pressing process

1. Choose good quality peanuts

The quality of the raw peanuts used in the oil pressing process significantly impacts the oil yield. It is crucial to select high-quality peanuts with optimal maturity and moisture content. Ensure that the peanuts are free from any contaminants or mold, as these can affect the oil extraction efficiency.

2. Pre-treatment of peanuts

Before the peanut oil pressing process, the peanuts should be thoroughly cleaned to remove impurities such as stones, debris, and dust. Proper drying of the peanuts is also important to reduce the moisture content, as excess moisture can lead to lower oil yield and quality.

Pre-treatment processes such as heating, steaming, or roasting the peanuts before pressing can help loosen the oil-bearing cells and enhance oil extraction efficiency. This step can improve the overall oil yield and quality of the extracted oil.

DOING peanuts pretreatment machines

DOING peanuts pretreatment machines

Henan doing group supplies peanuts pretreatment machines including peanut cleaning machine (vibrating screen, magnetic separator, destoner), crusher, flaking roller, woks with different processing capacities, etc. These machines can ensure pretreatment of peanuts to make them in a state suitable for pressing and to ensure maximum oil yield of peanuts.

3. Choose good peanut oil pressing machines

Choosing a high-quality peanut oil pressing machine designed for peanut oil extraction can significantly improve the oil yield. The peanut oil pressing machines produced by HENAN DOING GROUP use high-quality materials and can press efficiently while ensuring quality and improving the peanut oil yield. There are various types of peanut oil pressing machines for you to choose from. It is worth mentioning that one of DOING peanut oil pressing machines with temperature control, whihc can control the temperature, pressure and processing time in real time, playing a vital role in determining the oil yield.

Peanuts oil pressing machines

Peanuts oil pressing machines

The above is an introduction to the method to improve the oil yield of peanut oil pressing process. If you have any questions, you can leave a message and tell us. As a professional peanut oil pressing machine manufacturer, HENAN DOING will be happy to answer your questions. If you are looking for peanut oil pressing machines with a high oil rate, you may wish to give priority to us, a professional manufacturer, with after-sales services.

PREV:How to Ensure the Normal Operation of the Sunflower Oil Processing Machine?

PREV:How to Ensure the Normal Operation of the Sunflower Oil Processing Machine?

NEXT:What do I need to do to import cooking oil making machines from abroad to Zambia?

NEXT:What do I need to do to import cooking oil making machines from abroad to Zambia?

Leave a message

If you wanna to get more details about How to improve the oil yield of the peanut oil pressing process?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.