Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

- Guinea client orders 1TPD cooking oil refining plant from Henan Glory

- Henan Glory supplies cooking oil making machines to Nigerian overseas warehouse

What factors will influence the cooking oil manufacturing plant cost?

As professional manufacturer of cooking oil manufacturing plant, we can provide different capacities cooking oil manufacturing plant with different costs, since each client has different budget plans for starting the cooking oil business. Here, we would like to introduce you some factors that will influence the cooking oil manufacturing plant cost.

Different oil seeds need different pretreatment machines

Different oil seeds need different pretreatment machines

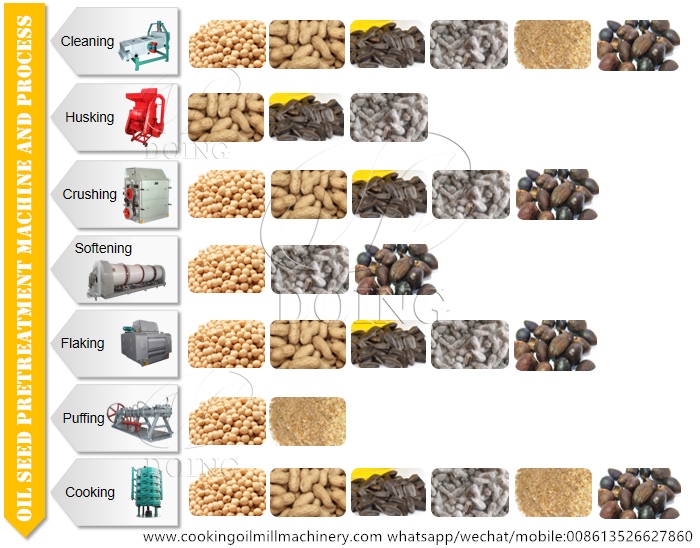

First, it depends on what raw materials you want to process. Some clients will choose common oil seeds like soybean, peanut, sunflower seed, rapeseed or sesame, and other clients may choose special oil seeds like palm fruits and palm kernels. After confirming your raw material, our engineer can recommend suitable machines for you accordingly and this may influence the cooking oil manufacturing plant cost.

Second, machine capacities will also influence the cooking oil manufacturing plant cost. For common oil seeds processing, we can provide pretreatment and pressing workshop, solvent extraction plant and oil refinery plant. If your input capacity is small, and only want oil seeds pretreatment and oil press machine, then your cooking oil manufacturing cost will be low.

1-5tph palm oil mill plant 3d picture

1-5tph palm oil mill plant 3d picture

For palm oil and palm kernel oil processing, we can provide pressing line, refinery line and fractionation plant. 1-5tph small scale palm oil mill plant is very popular among African clients. Of course, the cost is much lower.

Third and most importantly, the machine configuration and processing technology will also affect the cooking oil manufacturing plant cost. Like for more than 30tpd input capacity, only using pressing method will cost lower than that using pre-pressing and solvent extraction combination method. But the second method will get more crude oil, so that you can get more profits. It totally depends on your choice. Our engineers can design suitable proposal for you and give you best choice within your budget.

Starting a cooking oil manufacturing plant, there is much more to consider when refers to the total cost, like the civic cost, worker cost, tax cost and so on. Above are some factors that can influence the cooking oil manufacturing plant cost from the machine aspect. If you want to know more about how to start such cooking oil manufacturing plant and its cost, it is never too late to contact us!

PREV:An overview of rice bran oil solvent extraction process technology

PREV:An overview of rice bran oil solvent extraction process technology

NEXT:How to do a small scale vegetable oil production business?

NEXT:How to do a small scale vegetable oil production business?

Leave a message

If you wanna to get more details about What factors will influence the cooking oil manufacturing plant cost?, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.