Blog

- Ultimate Guide to Palm Kernel Oil Processing Machines: Types & How They Work

- What is the working principle of crude palm kernel oil expeller?

- Batch Type Edible Oil Refining Machine 1TPD to 20TPD

- Must-Know Maintenance Tips for Your Soybean Oil Extraction Machine

- Crude Oil Refining Equipment: Key Machines & Their Roles

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- 2tph Drum-type Palm Fruit Threshing Machine: New Order Secured by Henan Doing Nig. Co.,Ltd from Nigeria

- Shipping Confirmation: Mini Palm Oil Processing Line Successfully Handed Over from Our Nigeria Branch

- Heading to Kenya! Henan Glory's Custom Sunflower Oil Extraction Equipment Is On the Move

- Shipment Update: Small Scale Palm Oil Mill Plants Successfully Shipped to Nigeria

- Tailored for 1TPD: Henan Glory Wins Nigerian Small Scale Palm Oil Production Equipment Order

Must-Know Maintenance Tips for Your Soybean Oil Extraction Machine

Your soybean oil extraction machine is the heart of your production line, but its efficient operation isn’t something you can take for granted. Unexpected downtime or oil contamination can lead to big production losses and costly repairs. The good news? Most malfunctions are avoidable with a simple, consistent maintenance routine. Henan Glory is here to guide you on how to extend your equipment’s lifespan and consistently extract top-quality oil—all through careful daily maintenance.

Soybean oil

Soybean oil

Start with the non-negotiable daily task: thorough cleaning. Right after each shift, the most critical step is to remove all residual cake from the pressing chamber. Leftover cake hardens over time, which can clog the chamber, strain the motor, and even cause bacterial contamination in future batches. Don’t stop there—wipe down your soybean oil extraction machine’s exterior too, preventing oil and dust from building up into a hard, grimy layer that will be difficult to remove later. And if you’re shutting down for more than an hour? Be sure to pull out the screw shaft to remove any hidden cake scraps from the chamber, as this prevents buildup that could cause jams when restarting.

Next, lubrication is critical for preventing breakdowns of your soybean oil extraction machine. Key moving parts of the machine rely on proper lubrication to operate smoothly——for example, the screw shaft requires lubrication every shift to avoid dry grinding damage. For the gearbox, check the oil level every 50 operating hours, and perform a full oil quality inspection and oil change once a year. Do not overlook parts such as bearings and bushings either—they also require regular lubrication, and you must always unclog their oil holes if they become blocked. Skipping this step can lead to overheated bearings or seized components, resulting in costly repairs and unplanned downtime.

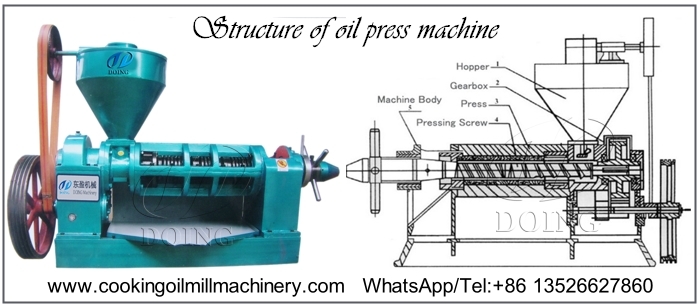

The structure of soybean oil extraction machine

The structure of soybean oil extraction machine

One of the most underrated maintenance skills? Learning to “listen” to your soybean oil extraction machine—it’ll tell you when something’s off. A sudden drop in pressing capacity, cloudy oil, or unusual noise are not just minor issues—they are warning signs. If you hear unusual noise, stop immediately: this could indicate that a metal fragment or stone has entered the chamber, or a fastener has come loose. If the oil is cloudy, this is likely because the soybeans are too dry or the machine’s temperature is too low (target a temperature of 60-70℃, at which the exterior feels hot to the touch). Excessive slag leakage? That’s usually worn press bars or excessive pressure in the chamber. Identifying these signs early and addressing issues—such as replacing worn screw shafts or adjusting the gaps between press bars—will maintain high oil quality and prevent more serious problems.

The way you shut down the soybean oil extraction machine is just as important as how you operate it—never simply turn off the power switch and leave. For any shutdown (even short ones), first close the feed plate 1-2 minutes before turning off the machine to stop feeding new soybeans. Then, reverse the screw shaft 2-3 turns to widen the cake outlet gap, allowing any leftover slag and cake inside the chamber to be fully discharged.

Three types of soybean oil extraction machine

Three types of soybean oil extraction machine

Finally, when a production cycle ends and the machine will be idle for a period of time, proper storage will prevent it from corroding. Perform a complete disassembly of key components: remove the screw shaft, clean the press bars, and wipe down the cake outlet ring. Apply a fresh layer of oil to these components to prevent rust, then store them in a clean, dry environment. This ensures that when you are ready to resume pressing, your soybean oil extraction machine will be in optimal condition—free of rust, clogs, and delays.

Effective maintenance is the cornerstone of long-term efficiency for your soybean oil extraction machine. At Henan Glory, we do not just sell reliable cooking oil processing equipment—we also partner with you to ensure your success. Our comprehensive technical support and spare parts services are designed to keep your production line operating smoothly, allowing you to focus on producing high-quality oil.

PREV:Batch Type Edible Oil Refining Machine 1TPD to 20TPD

PREV:Batch Type Edible Oil Refining Machine 1TPD to 20TPD

NEXT:Crude Oil Refining Equipment: Key Machines & Their Roles

NEXT:Crude Oil Refining Equipment: Key Machines & Their Roles

Leave a message

If you wanna to get more details about Must-Know Maintenance Tips for Your Soybean Oil Extraction Machine, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.