Blog

- What Is the Complete Process to Make Peanut Oil, from Raw Peanuts to Bottled Oil?

- What impurities can edible oil refining equipment remove during processing?

- Ultimate guide to palm kernel oil processing machines: types & how they work

- What is the working principle of crude palm kernel oil expeller?

- Batch type edible oil refining machine 1tpd to 20tpd

Contact Us

- Mobile/WhatsApp:

008613526627860

- Phone:

008637156771823

- Email:

sales@doingoilmachine.com

News

- Deal closed: YZYX70WZ sunflower oil press order for Cuban client

- A Nigerian customer successfully ordered 1tph palm fruit oil milling machines

- Henan Glory secures New Year order for a peanut oil press from Kenya

- Togolese farmers invest in Henan Glory's soybean oil extraction machines for an integrated livestock operation

- Henan Glory wins Nigerian order for YZYX-70 soybean oil press

The introduction of cotton seed oil processing

There are two main cotton seed oil processing methods: one is the pretreatment pressing method, and the other is the solvent extraction method. Different extraction methods use different cotton seed oil processing equipment. Pressing is a process of obtaining cotton seed oil from cotton seed by mechanical pressing. Solvent extraction is a process of obtaining cotton seed oil from processed cotton seed cake by using the principle of solvent and oil miscibility. Below is the introduction of cotton seed oil processing methods.

1. The pressing method of cotton seed oil processing

The cotton seed oil production line by pressing method includes the following steps: cotton seed pretreatment, cotton seed oil pre-pressing and cotton seed oil pressing. The purpose of cotton seed pretreatment is to clean impurities in cotton seed, adjust the moisture, temperature and internal structure of cotton seed, so that cotton seed can reach a good state before pressing, thereby improving the production efficiency of cotton seed oil. The cotton seed pretreatment equipment used includes cleaning equipment (magnetic separator, cleaning screen and stone remover), shelling equipment, kernel and shell separation screen, embryo rolling machine, steaming and frying pan and other equipment.

Next, the treated cotton seeds are pressed twice using a cotton seed oil pre-press and a cotton seed oil press, and the cotton seed oil obtained retains its natural aroma and its nutrients are not destroyed. At this point, the cotton seed oil processing by pressing is complete.

Cotton seed oil mechanical pressing line(20-50tpd)

Cotton seed oil mechanical pressing line(20-50tpd)

2. The solvent extraction method of cotton seed oil processing

Similar to the pressing method, the solvent extraction method also includes cotton seed pretreatment and cotton seed oil pre-pressing. The cotton seed pretreatment equipment adjusts the internal structure of cotton seed to a state suitable for extraction. After being processed by the cotton seed oil pre-pressing machine, raw cotton seed oil and cotton seed cake can be obtained. The cotton seed cake is transported to the extraction workshop for further production of cotton seed oil.

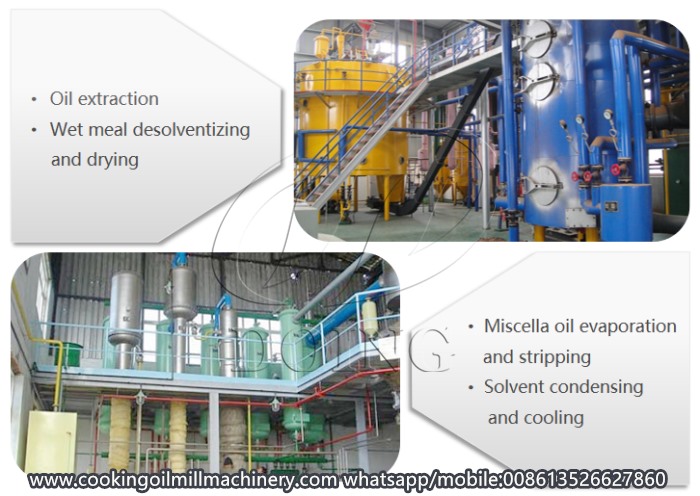

The cotton seed oil production line by solvent extraction is divided into four steps: the first is the extraction system, the second is the wet meal desolventization, the third is the mixed oil evaporation and stripping, and the fourth is the solvent recovery system. In the cotton seed oil extraction process, the cotton seed meal and the solvent are first contacted to make the oil and solvent in the meal blend to form a mixed oil. After the mixed oil is evaporated and stripped by the mixed oil treatment system, the solvent is vaporized and discharged to obtain crude cotton seed oil.

The cottonseed oil solvent extraction plant(100TPD-2000TPD)

The cottonseed oil solvent extraction plant(100TPD-2000TPD)

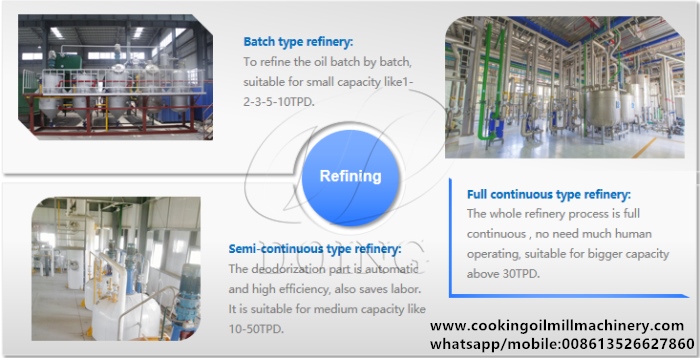

3. The refining method of cotton seed oil processing

Cotton seed oil contains a harmful substance to the human body - gossypol, whether it is extracted by pressing or solvent extraction method, cotton seed oil must be refined before consumption. Cotton seed oil refining equipment can remove colloidal impurities, free fatty acids, pigments, odors and other impurities in cotton seed oil, and improve the stability and market value of cotton seed oil. The cotton seed oil refining process includes degumming, deacidification, decolorization and deodorization. After refining, cotton seed oil that meets national standards can be obtained and sold on the market to obtain profit income.

Three types cottonseed oil refinery plant

Three types cottonseed oil refinery plant

Above is the introduction of cotton seed oil processing methods. The two cotton seed oil production processes have similarities and obvious differences, but there is no distinction between good and bad. It is just necessary to consider your cotton seed quality, processing volume, market requirements for finished oil, investment budget and other factors, and then select the appropriate cotton seed oil processing. The same production process can also choose to configure different cotton seed oil processing equipment according to the budget cost. In short, Henan Glory Company can customize suitable cotton seed oil processing equipment for you. We can realize every reasonable requirement of yours and satisfy you. If you need cotton seed oil processing equipment, please feel free to contact us.

PREV:What operational training does Henan Glory Company provide for edible oil processing plant project?

PREV:What operational training does Henan Glory Company provide for edible oil processing plant project?

Leave a message

If you wanna to get more details about The introduction of cotton seed oil processing, you can send E-mail to sales@doingoilmachine.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line